Gary Works Photograph Album

This photograph album compiled by U.S. Steel includes 63 prints documenting the steel works plant in Gary, Indiana. Photo captions are from the original album.

Part of the United States Steel Corporation photographs collection.

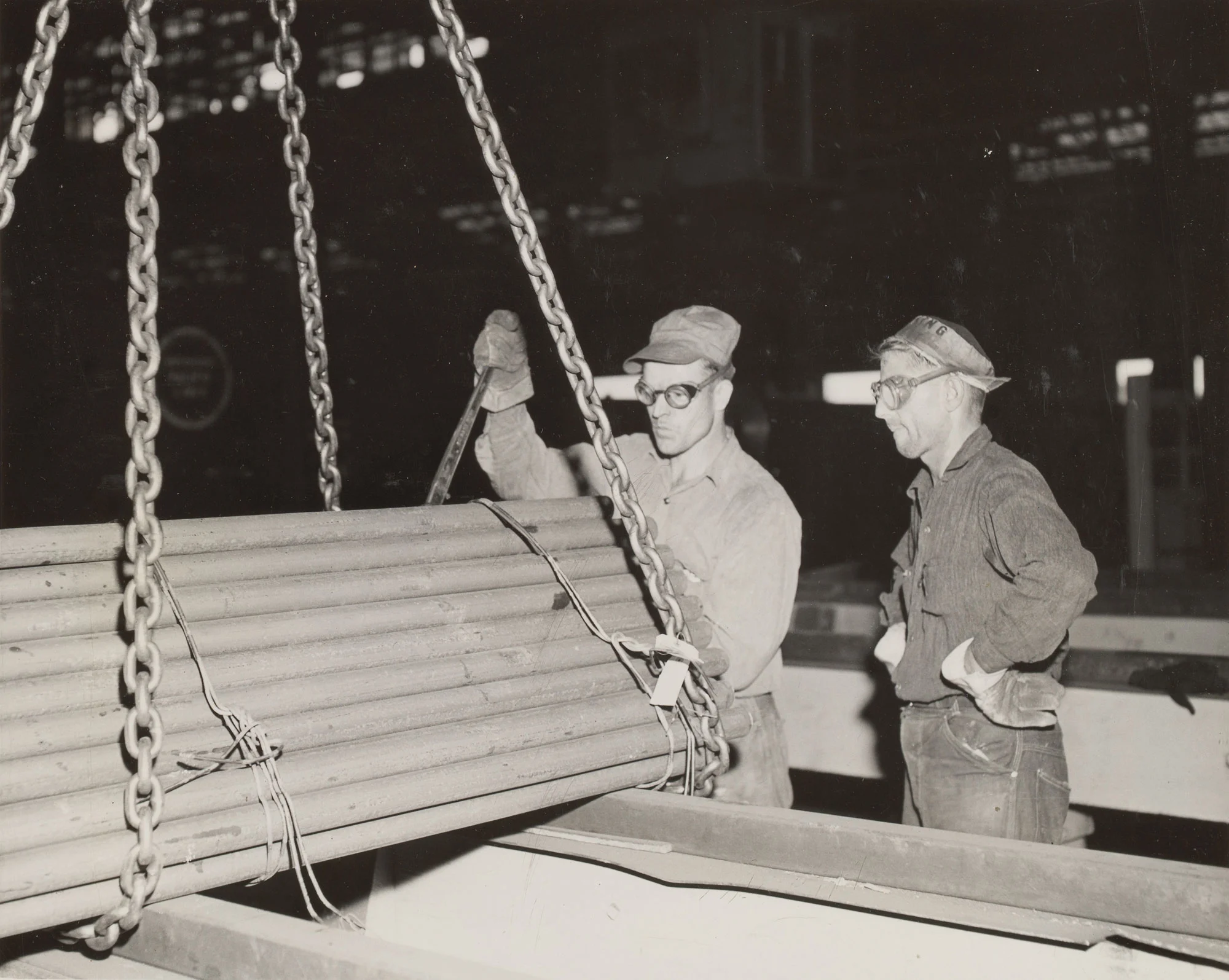

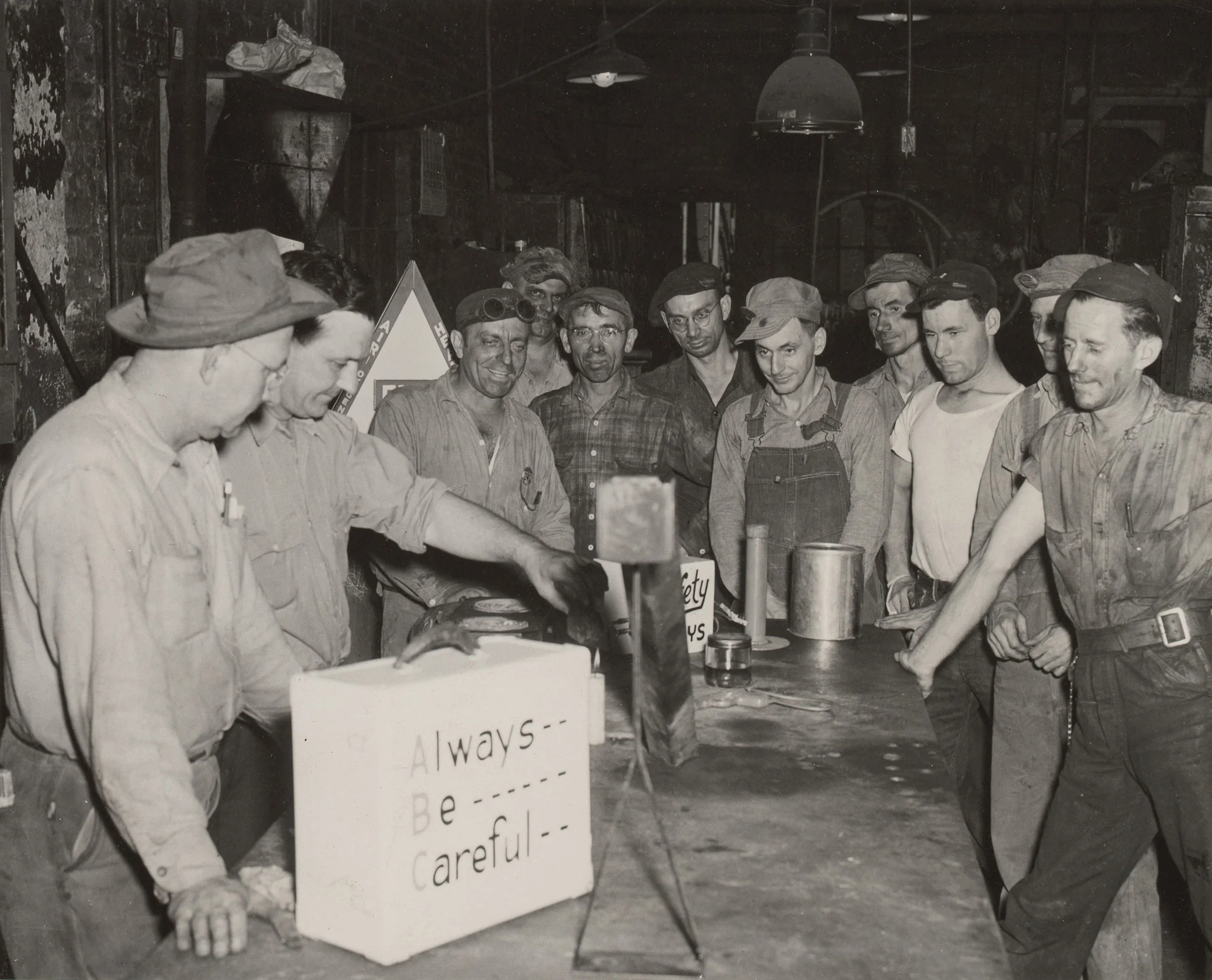

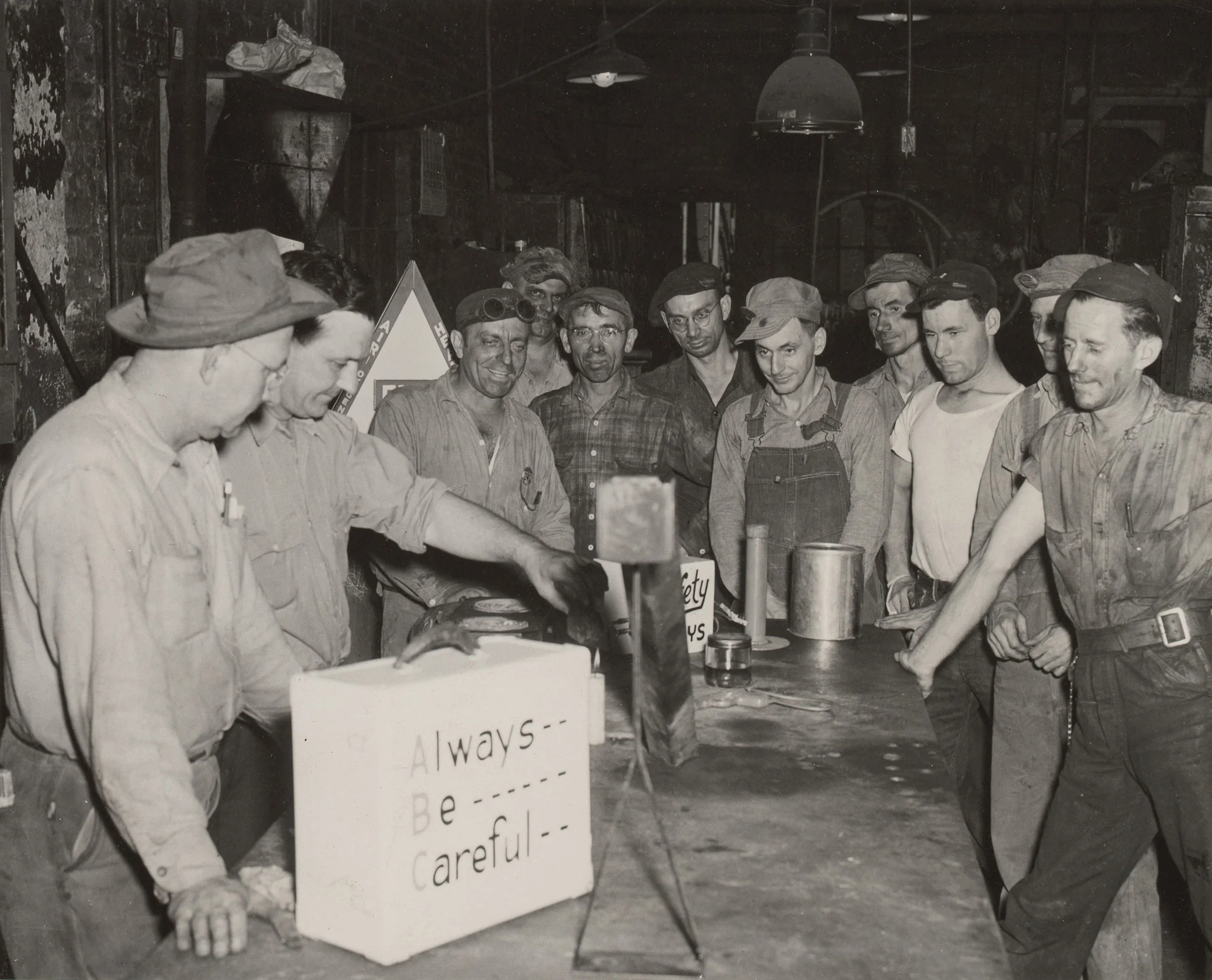

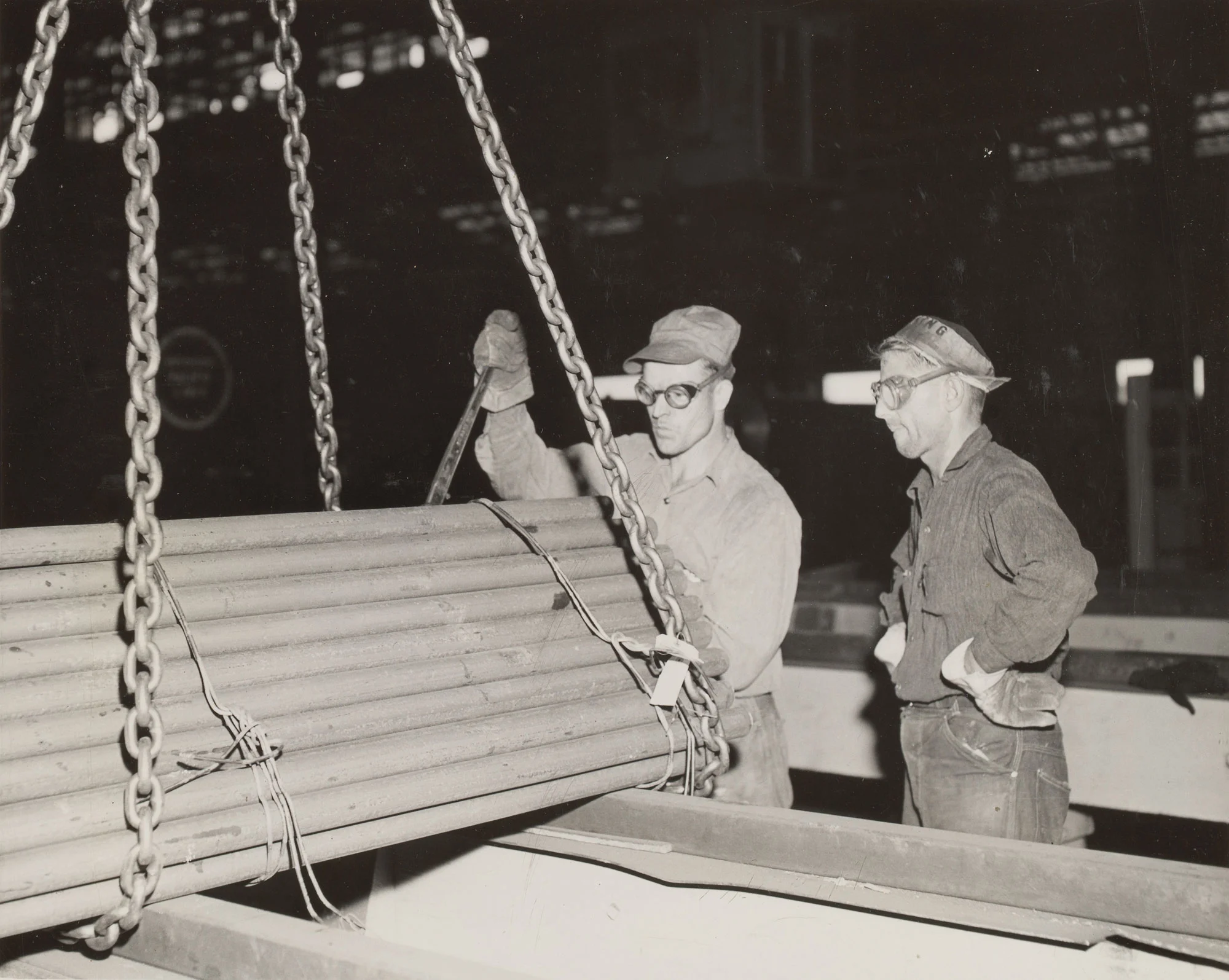

Safety instruction to the new employee at U.S. Steel's Gary Steel Works, Gary, Indiana, regarding the safe way to cut wire on bundles of steel.

BIRD'S EYE VIEW of a portion of the world's largest steel mill, the Gary, Indiana, Works of United States Steel. In the background on the right can be seen six of the plants twelve blast furnaces and on the left two of the open hearth shops. (Fritz Henle, photographer)

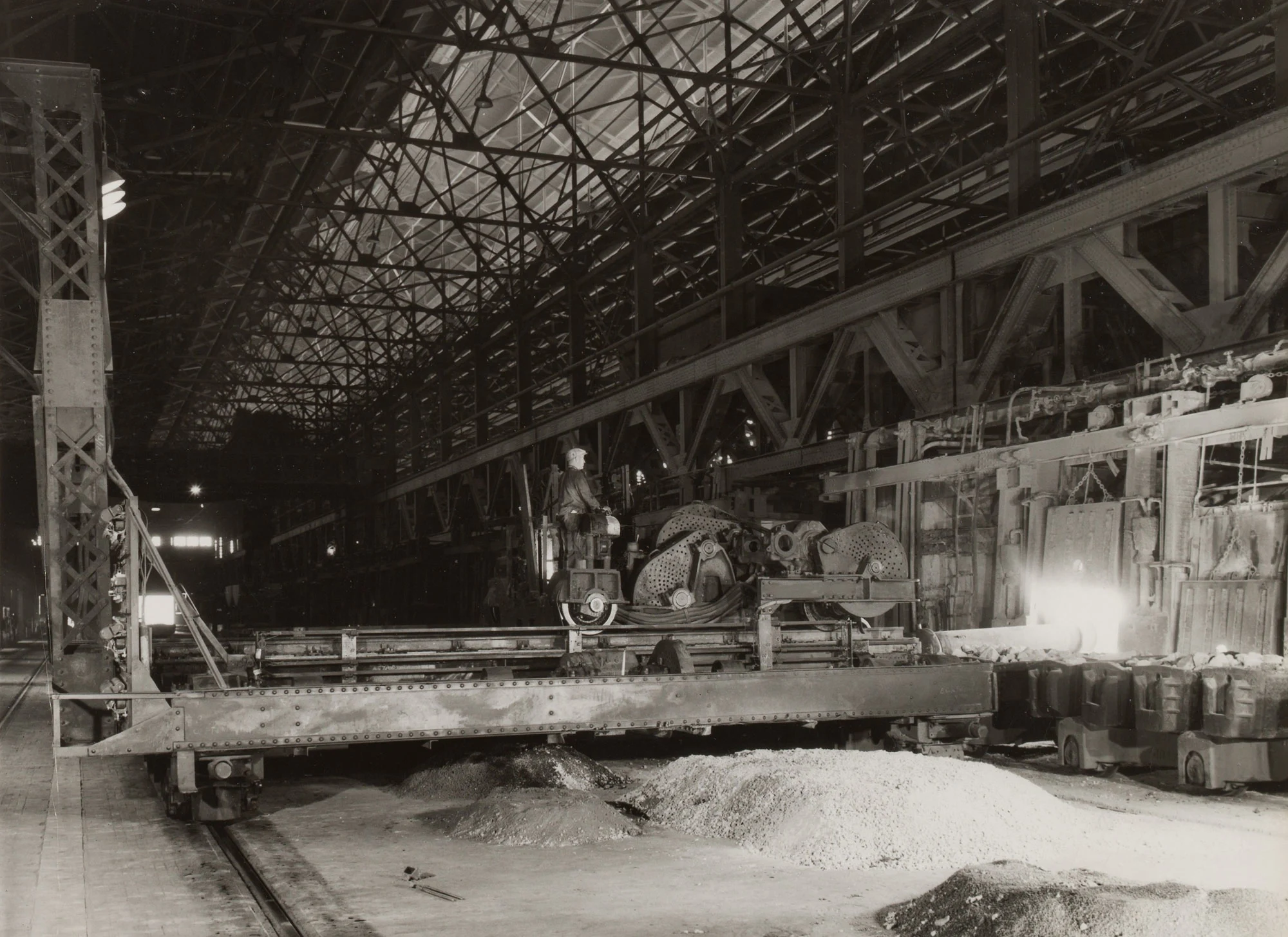

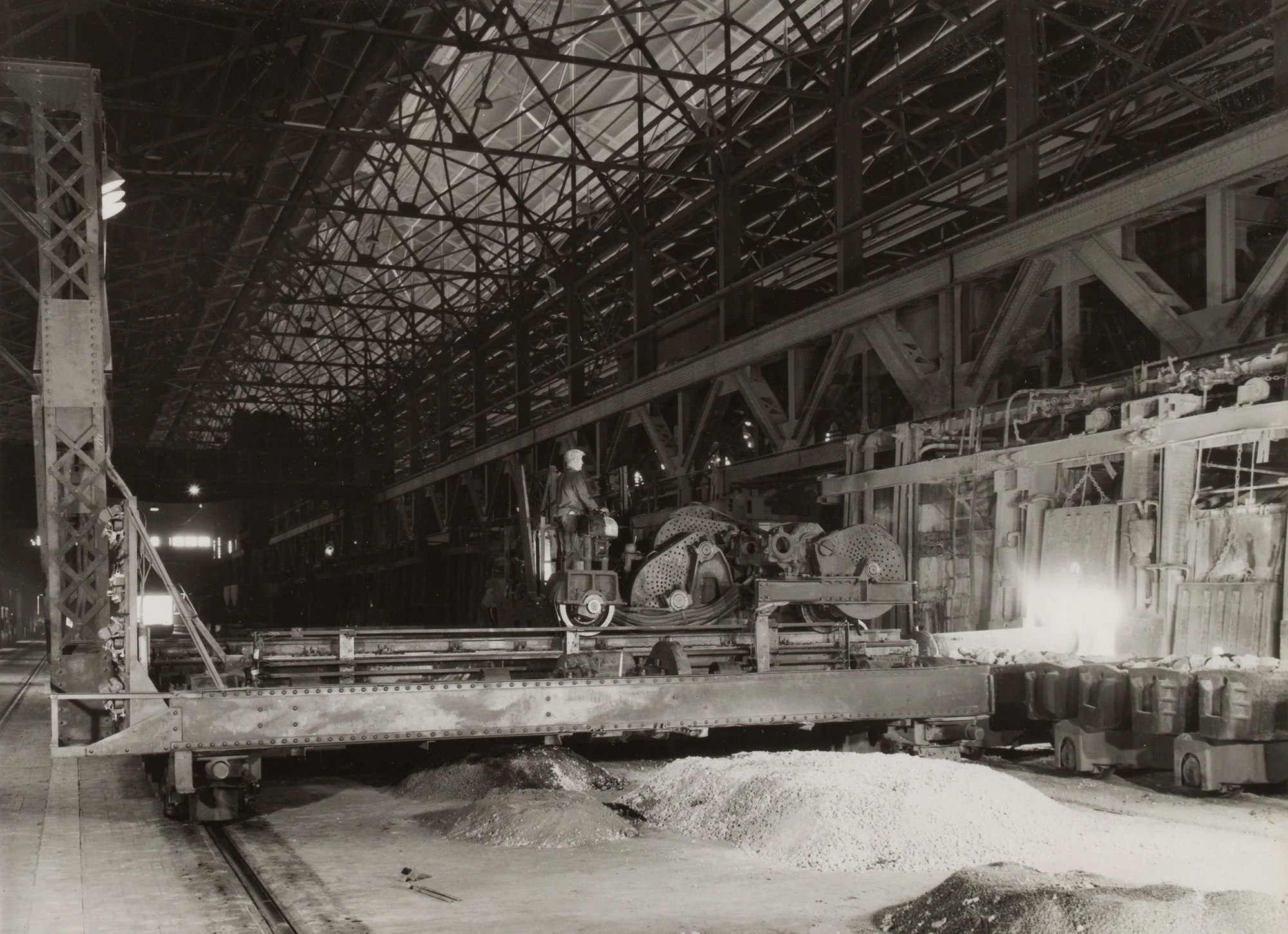

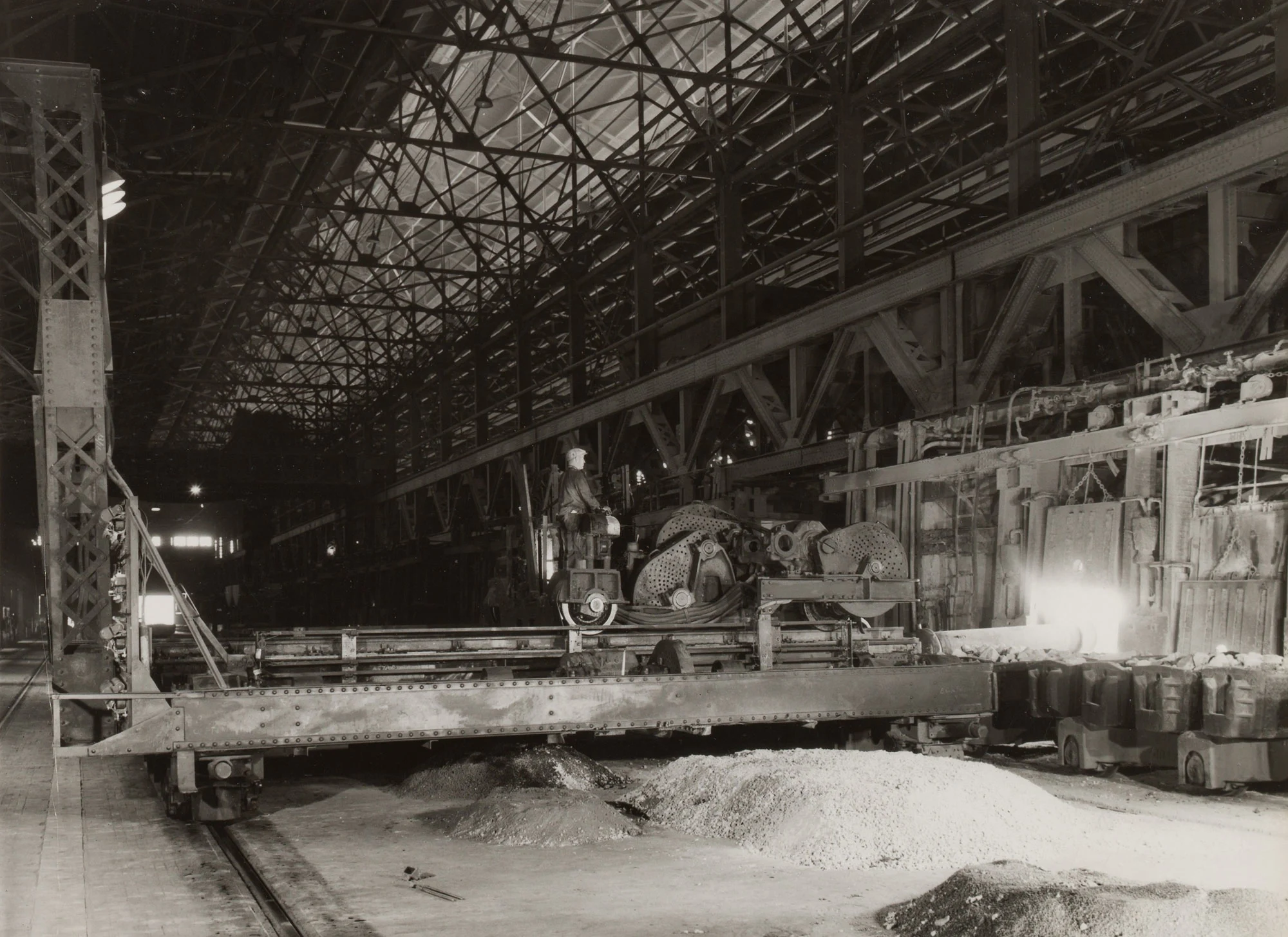

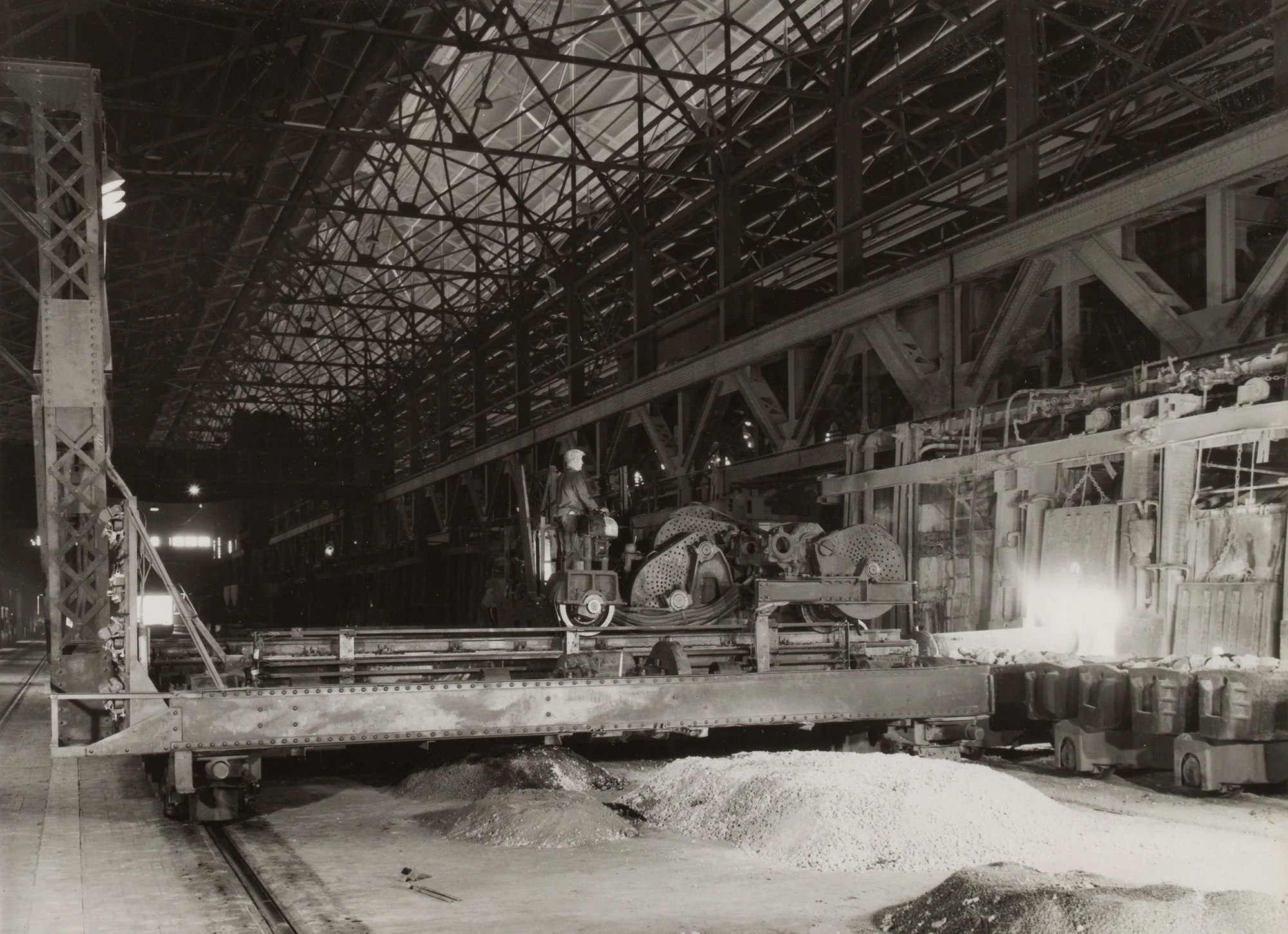

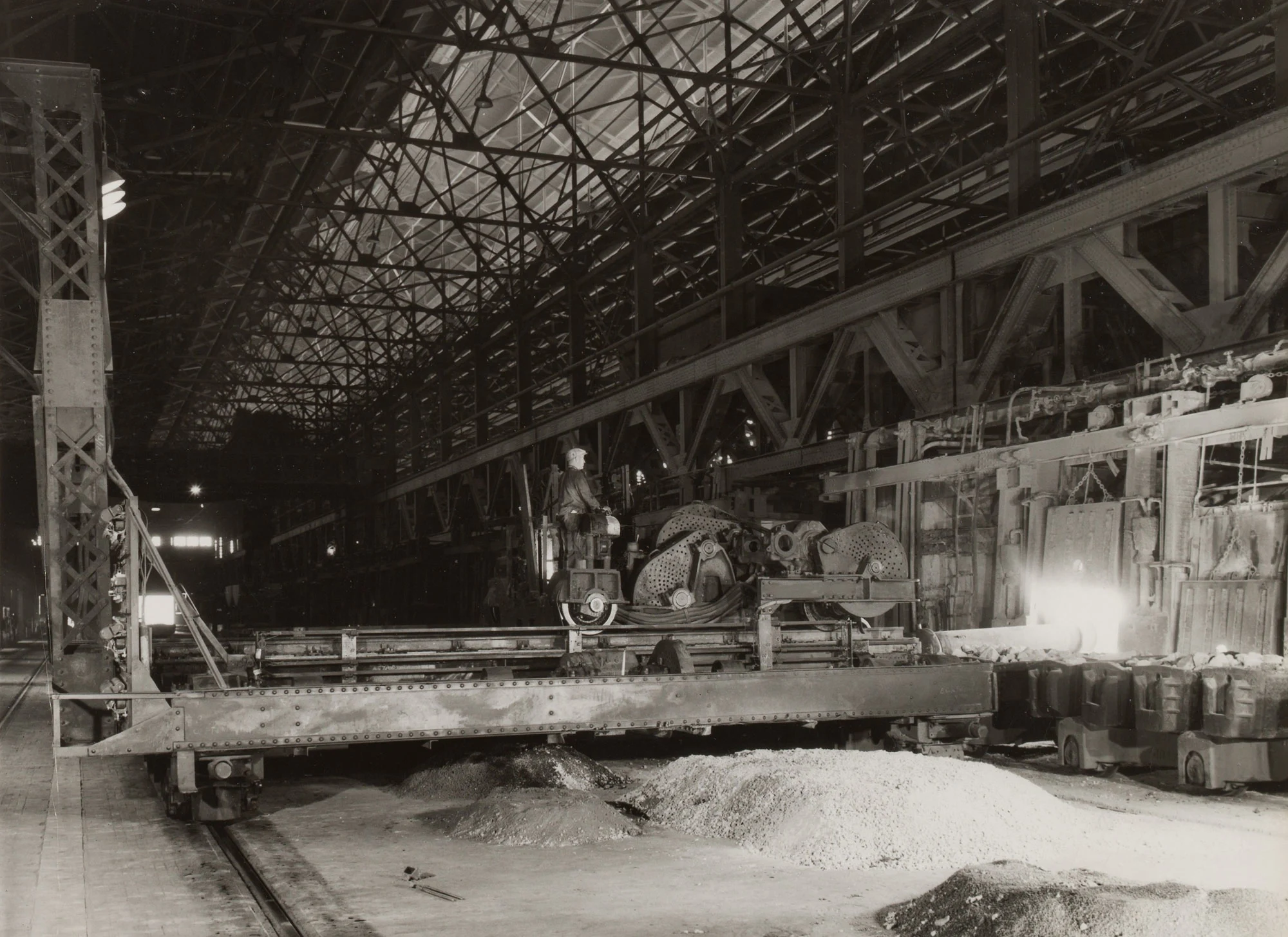

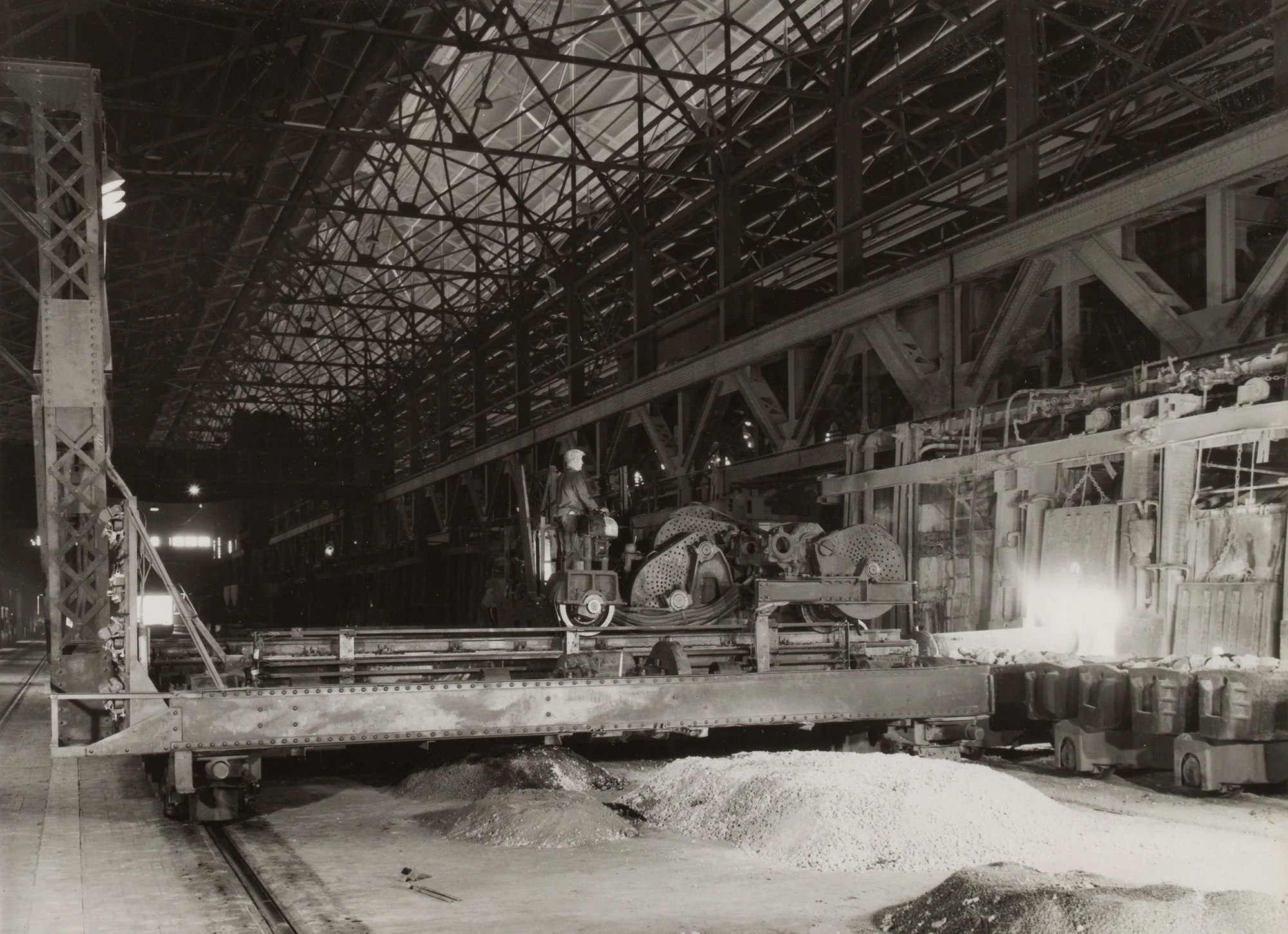

Charging machine with view of the "peel" as contents of box is dumped into No. 88 furnace at U.S. Steel's Gary Steel Works, Gary, Indiana. The cluster of 3500-watt lamps near the top of A-frame, supporting power collector bars, gives excellent lighting conditions. On the charging floor can be seen a neat pile of ground basic slag, besides a larger pile of burned dolomite in the near foreground, a pile of granite dolomite. (Fred Korth, photographer)

Molten iron from one of the 12 blast furnaces at U.S. Steel's Gary, Indiana, Works runs into a ladle car, in foreground, for transfer to an open hearth stop. (Fritz Henle, photographer)

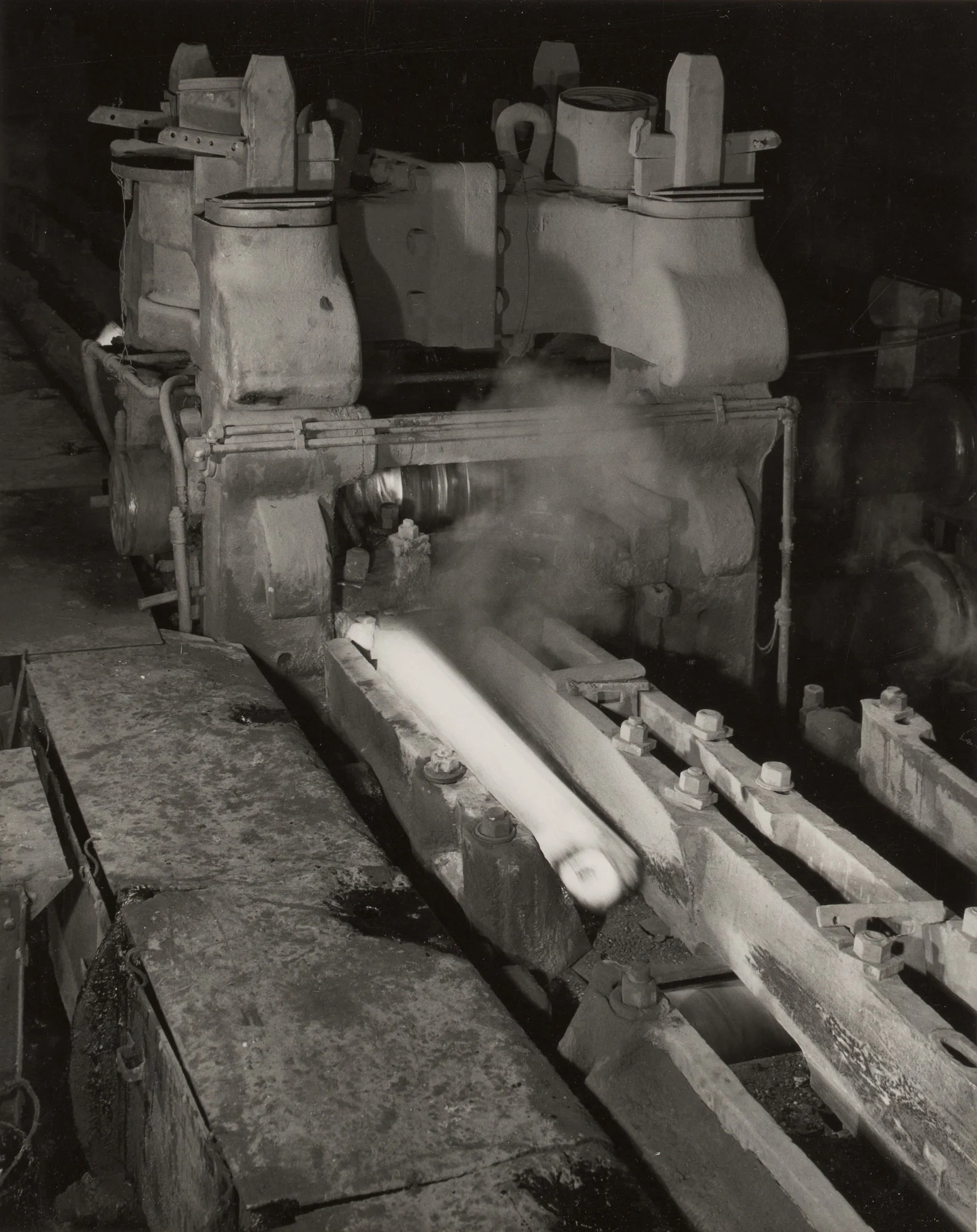

Tubing is welded electrically at the No. 5 weld mill of U.S. Steel's National Tube Company plant in Gary, Indiana. (Fritz Henle, photographer)

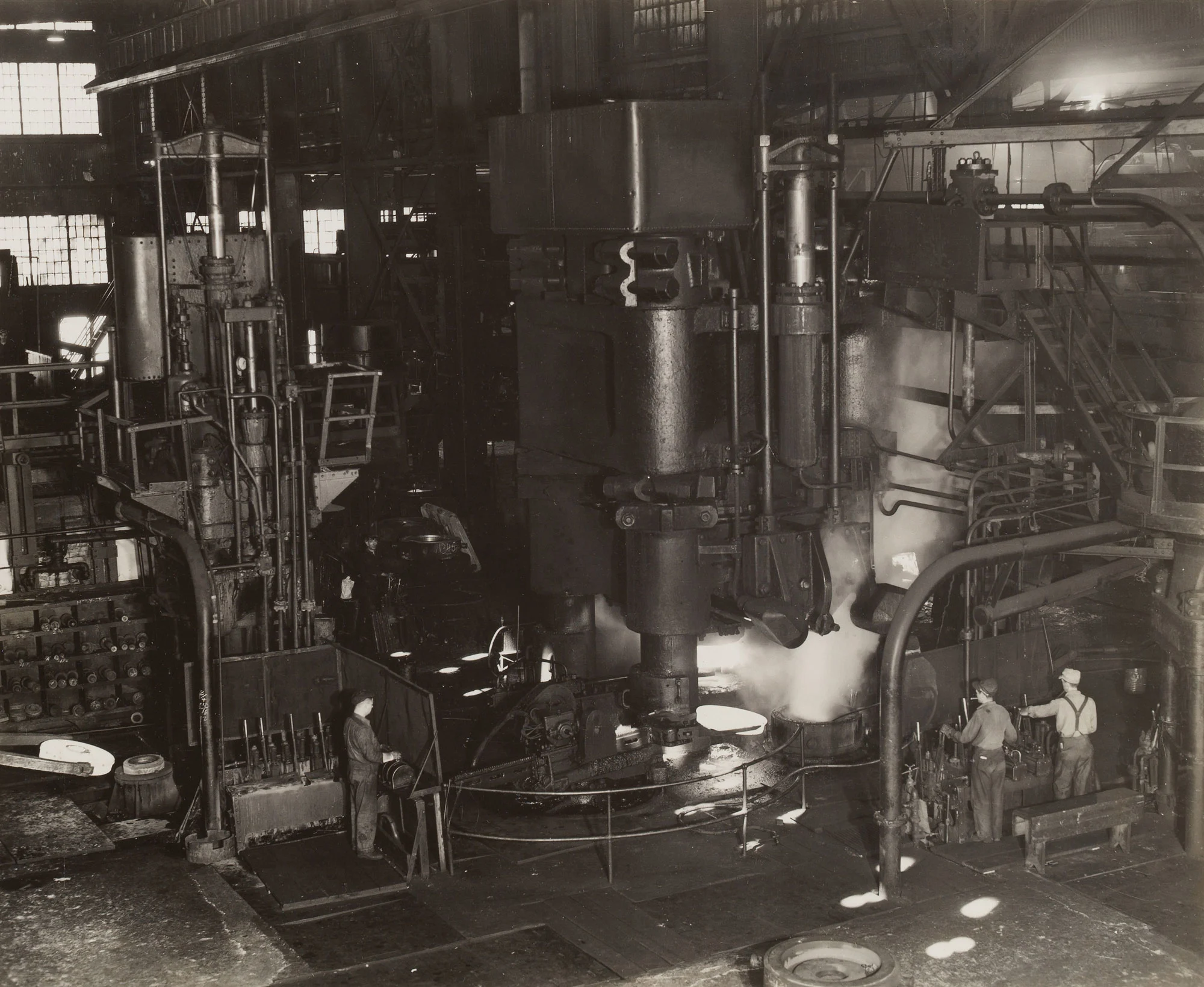

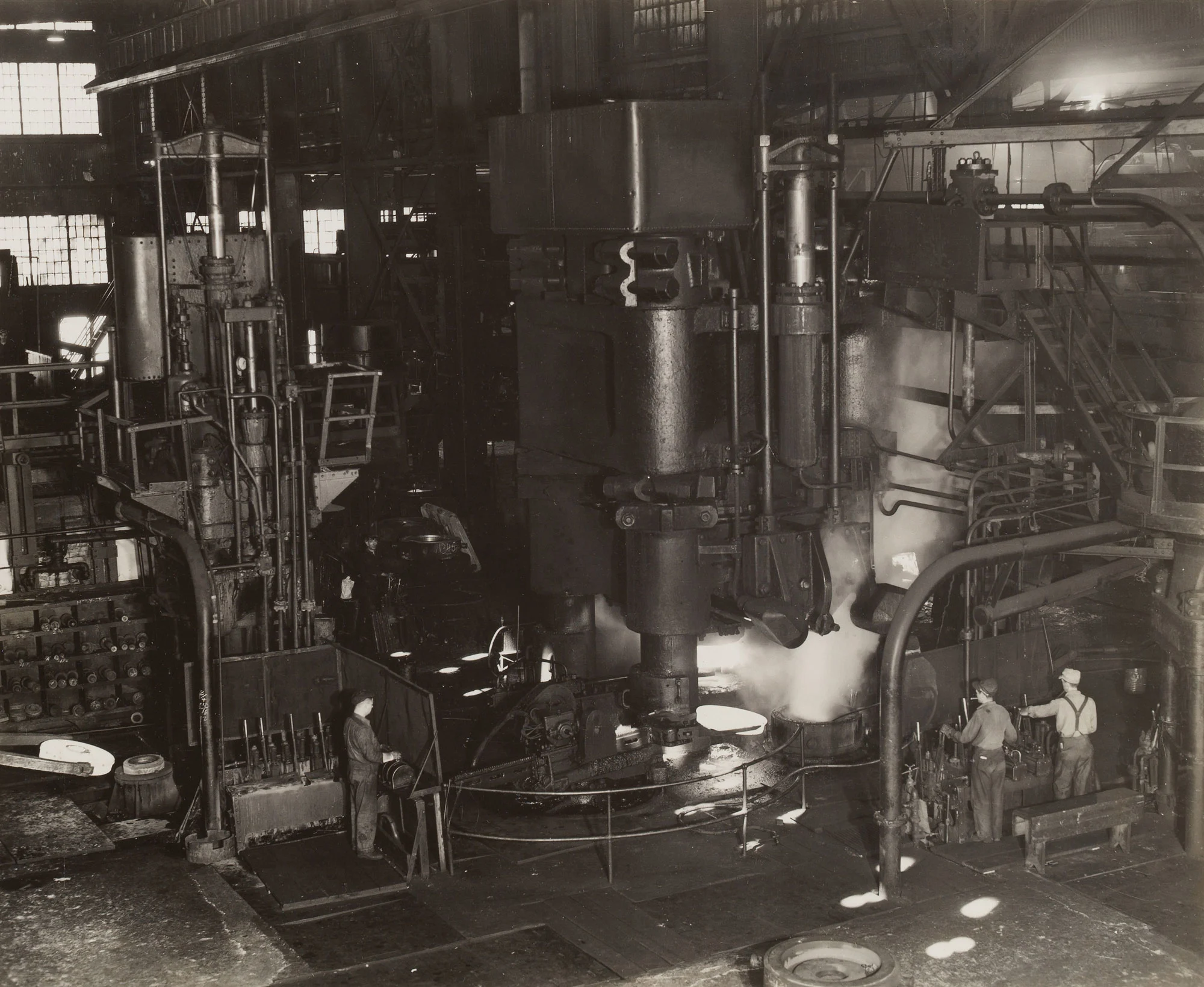

A view of the charging floor in the open hearth building at U.S. Steel's Gary Steel Works, Gary, Indiana. One of the furnaces is receiving a charge of molten iron from the blast furnace.

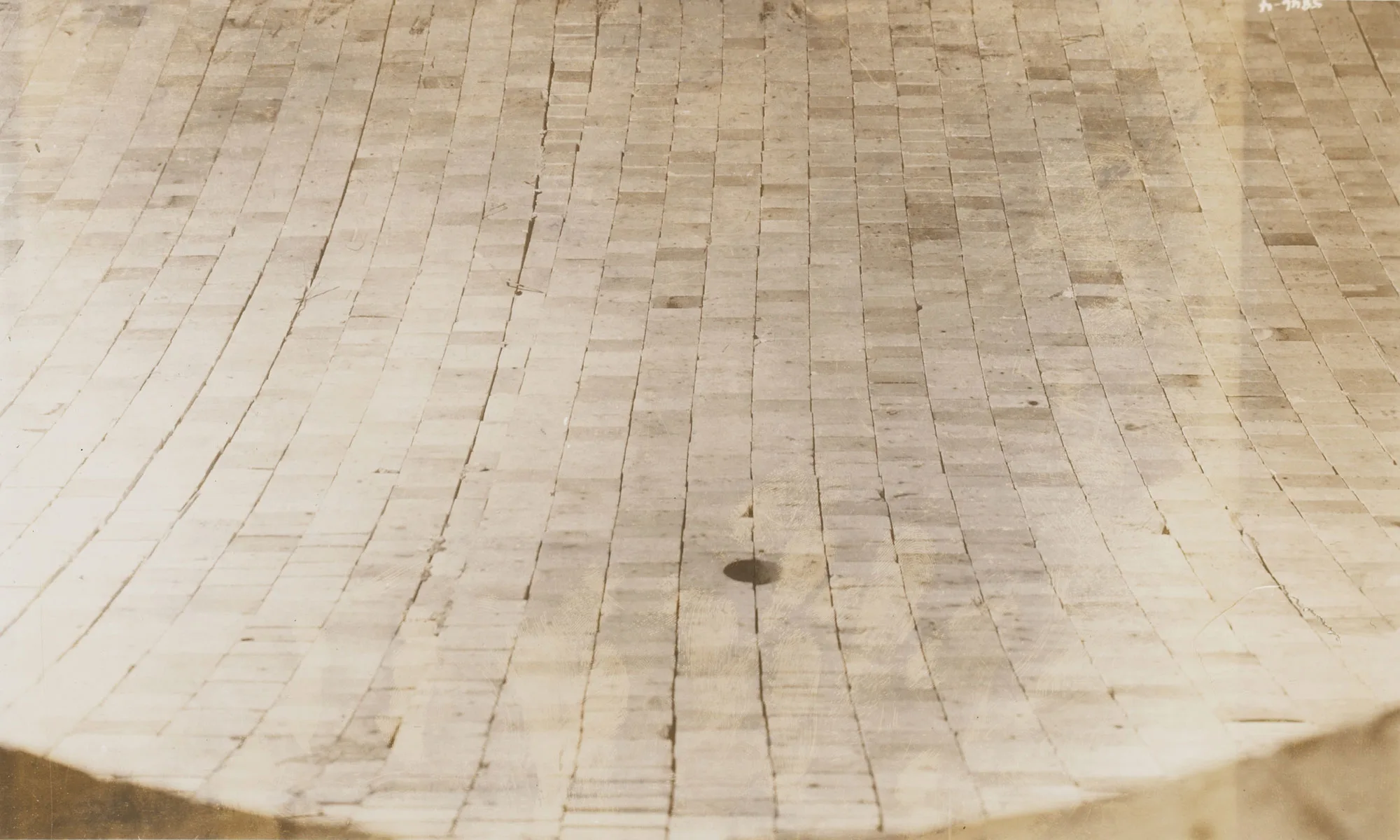

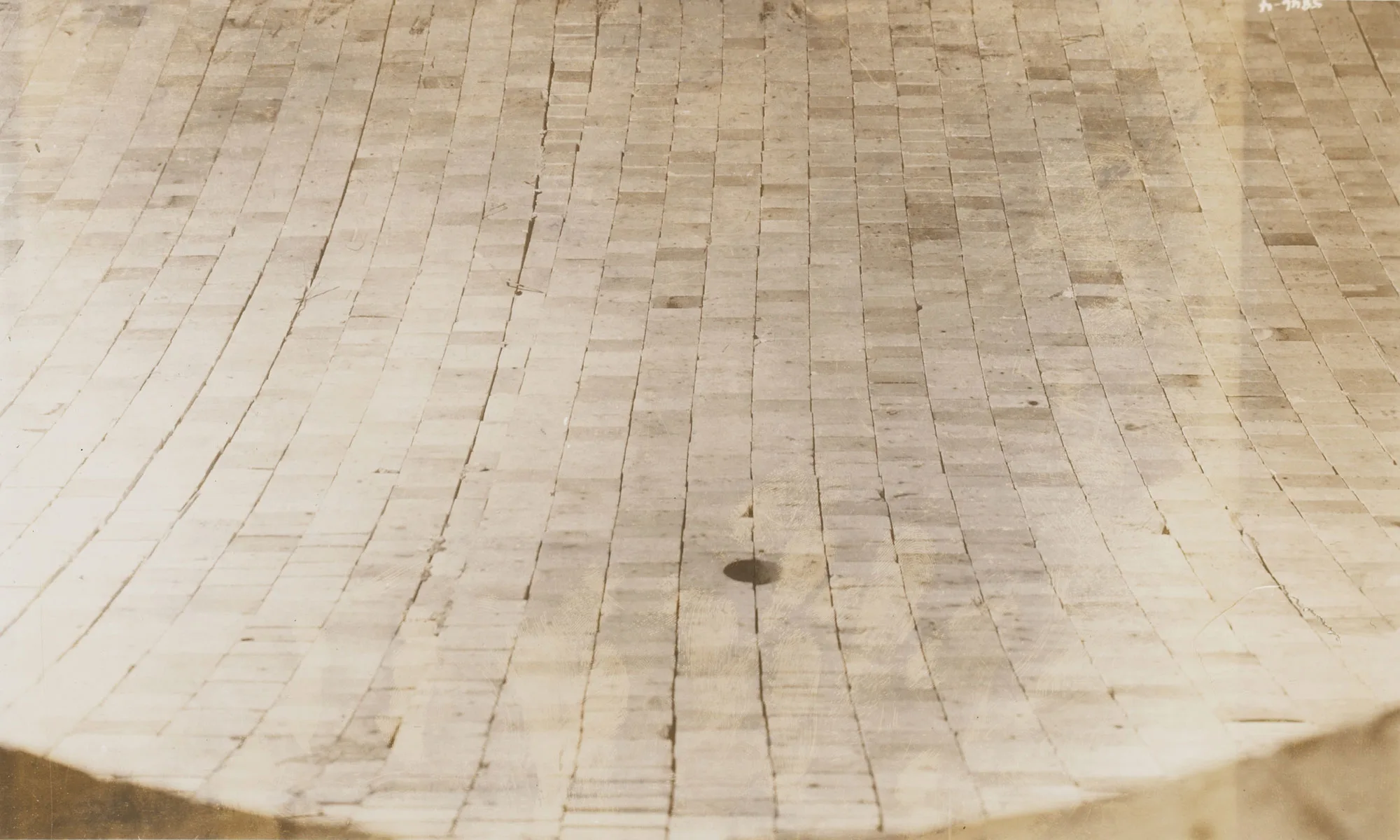

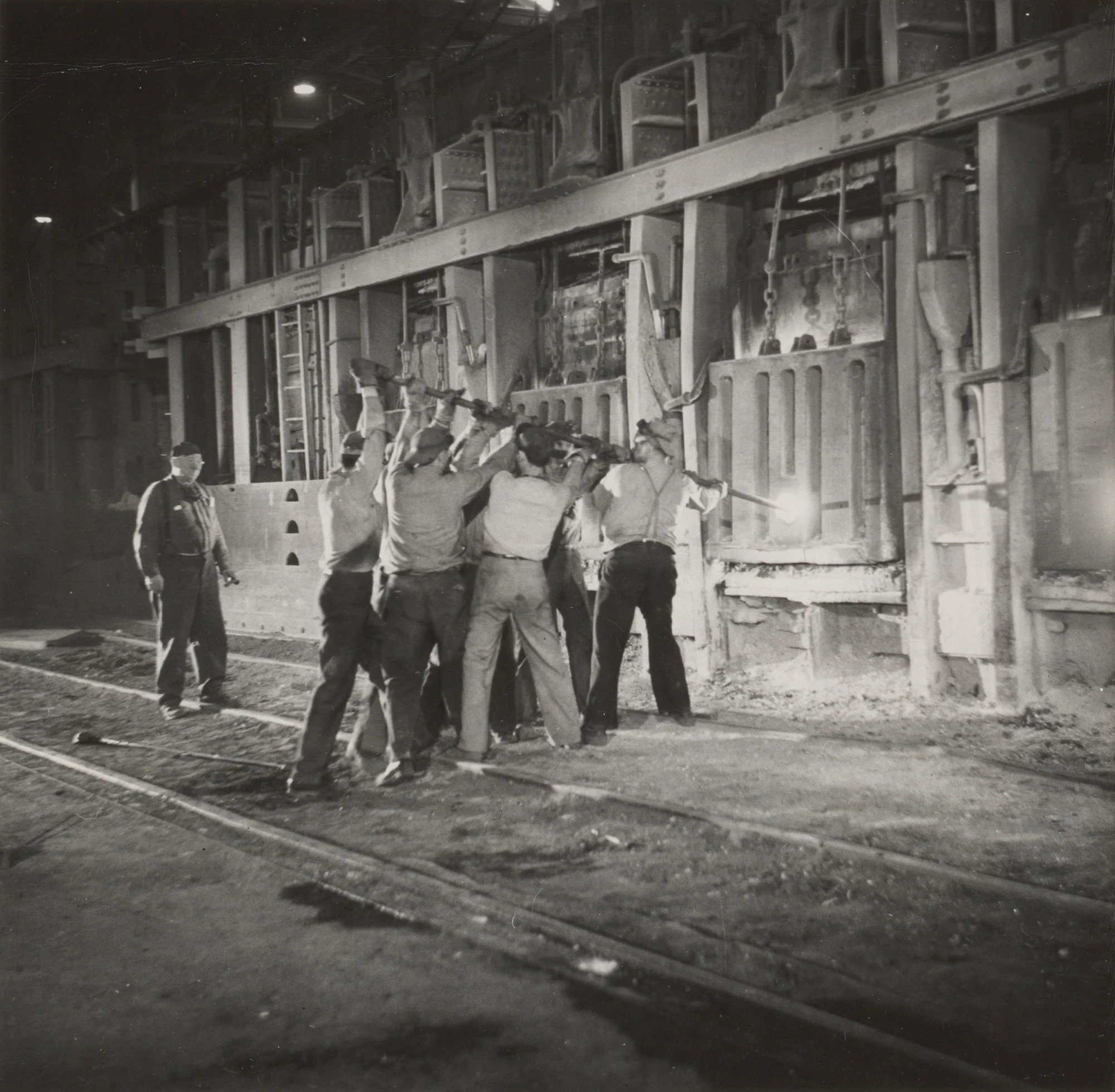

Open hearth crew "making bottom" with dolomite in an open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana.

Charging machine with view of the "peel" as contents of box is dumped into No. 88 furnace at U.S. Steel's Gary Steel Works, Gary, Indiana. The cluster of 3500-watt lamps near the top of A-frame, supporting power collector bars, gives excellent lighting conditions. On the charging floor can be seen a neat pile of ground basic slag, besides a larger pile of burned dolomite in the near foreground, a pile of granite dolomite. (Fred Korth, photographer)

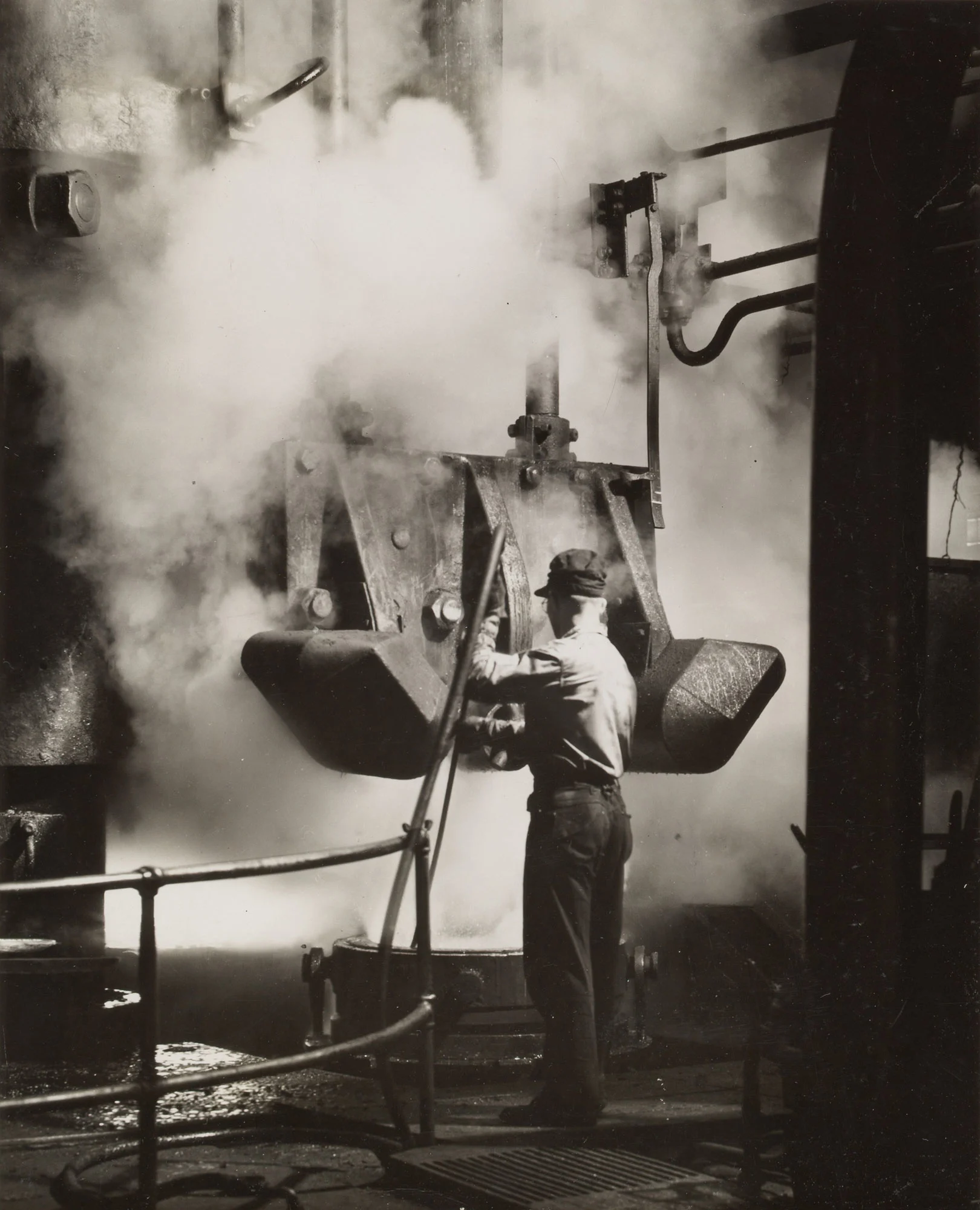

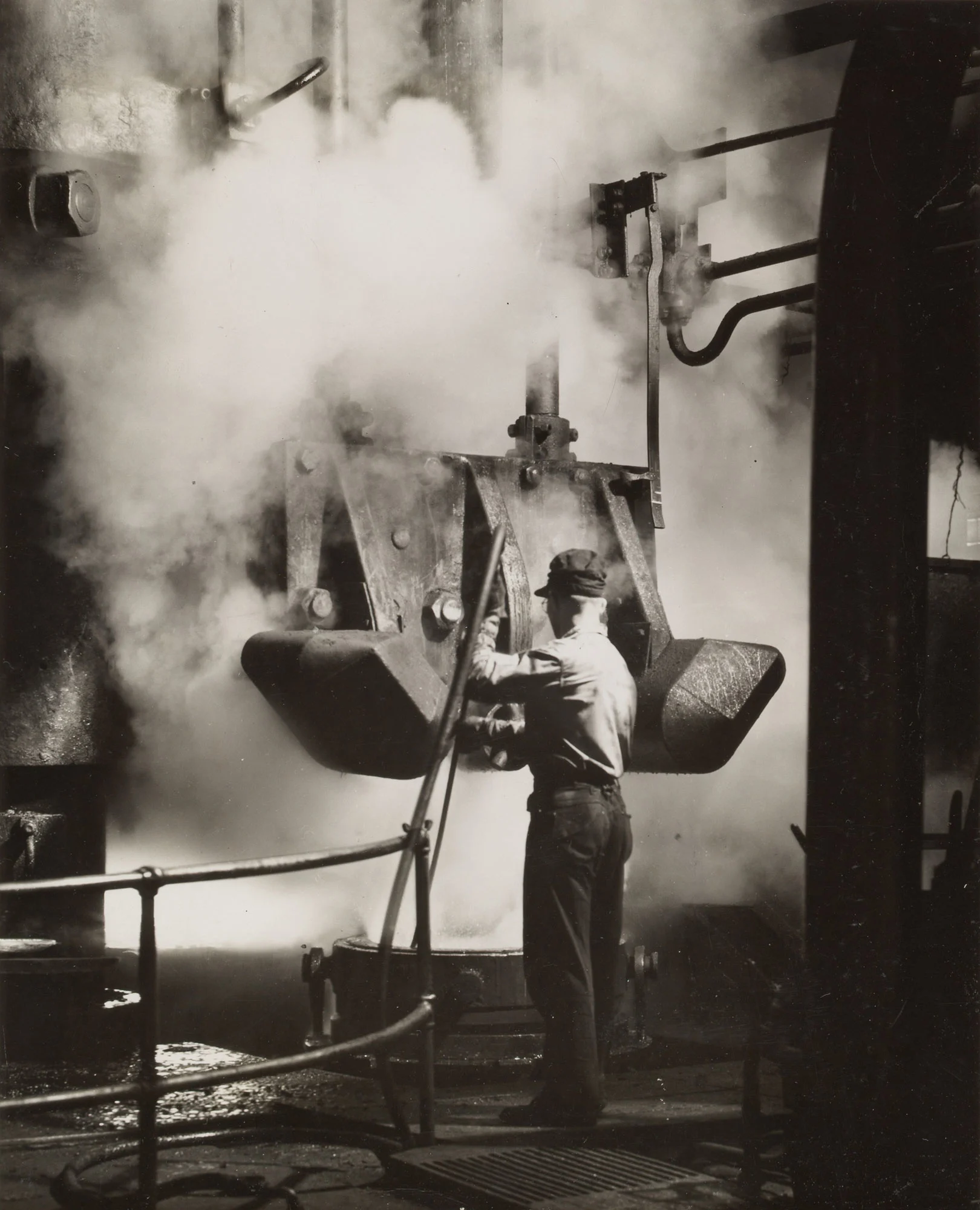

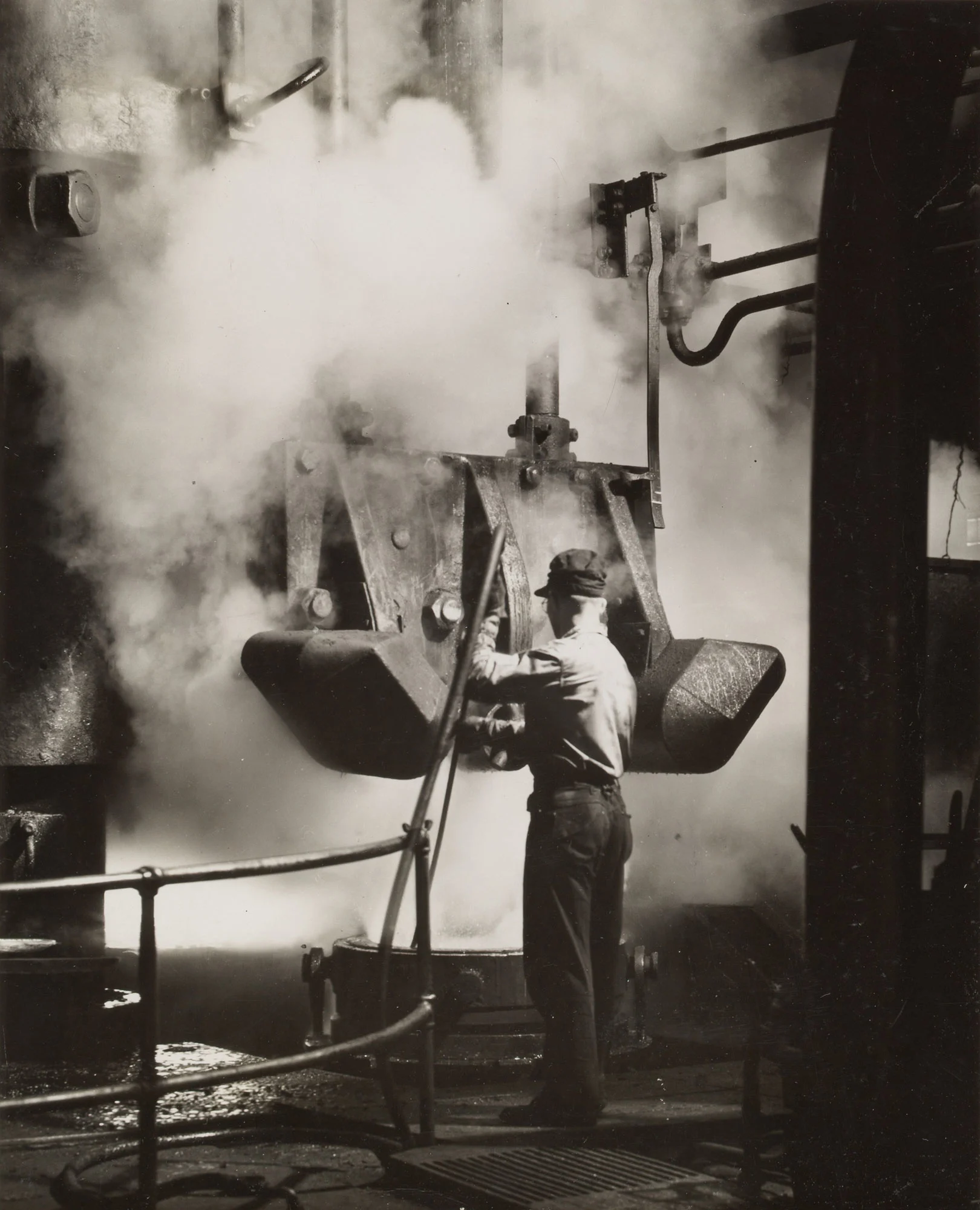

One hundred tons of molten iron is shown being poured into an open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana.

Pouring 100 tons of blast furnace iron into an open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana. (Fred Korth, photographer)

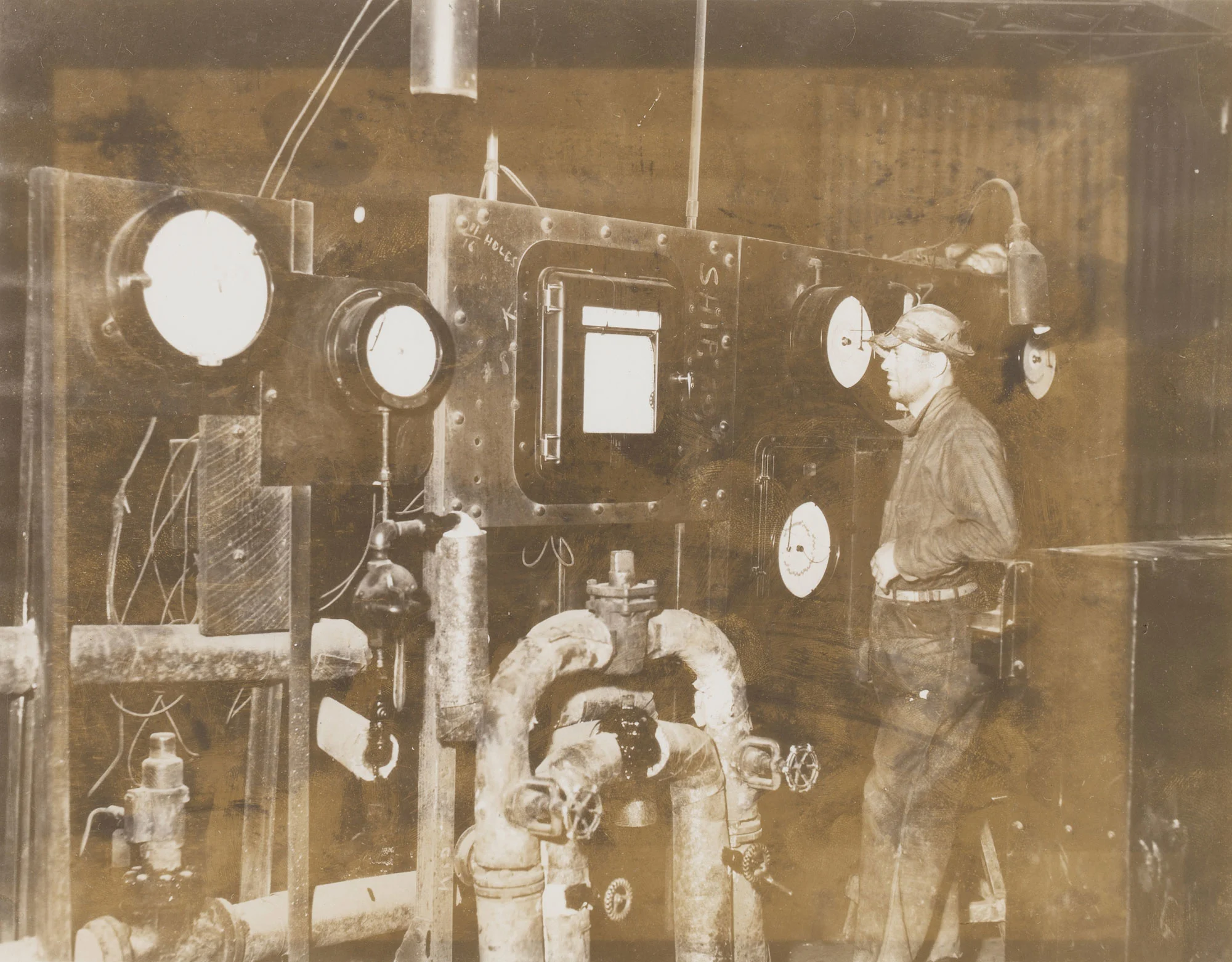

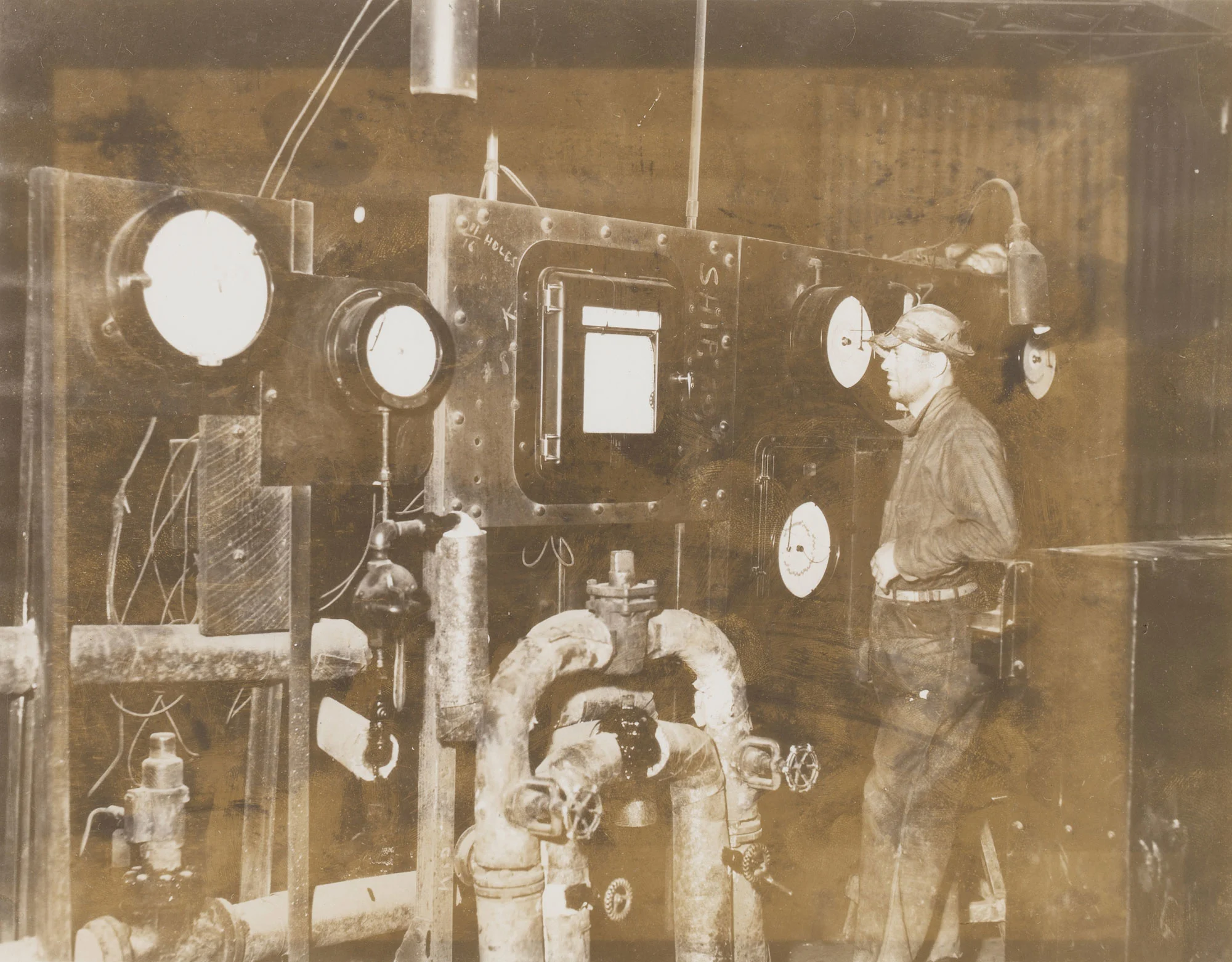

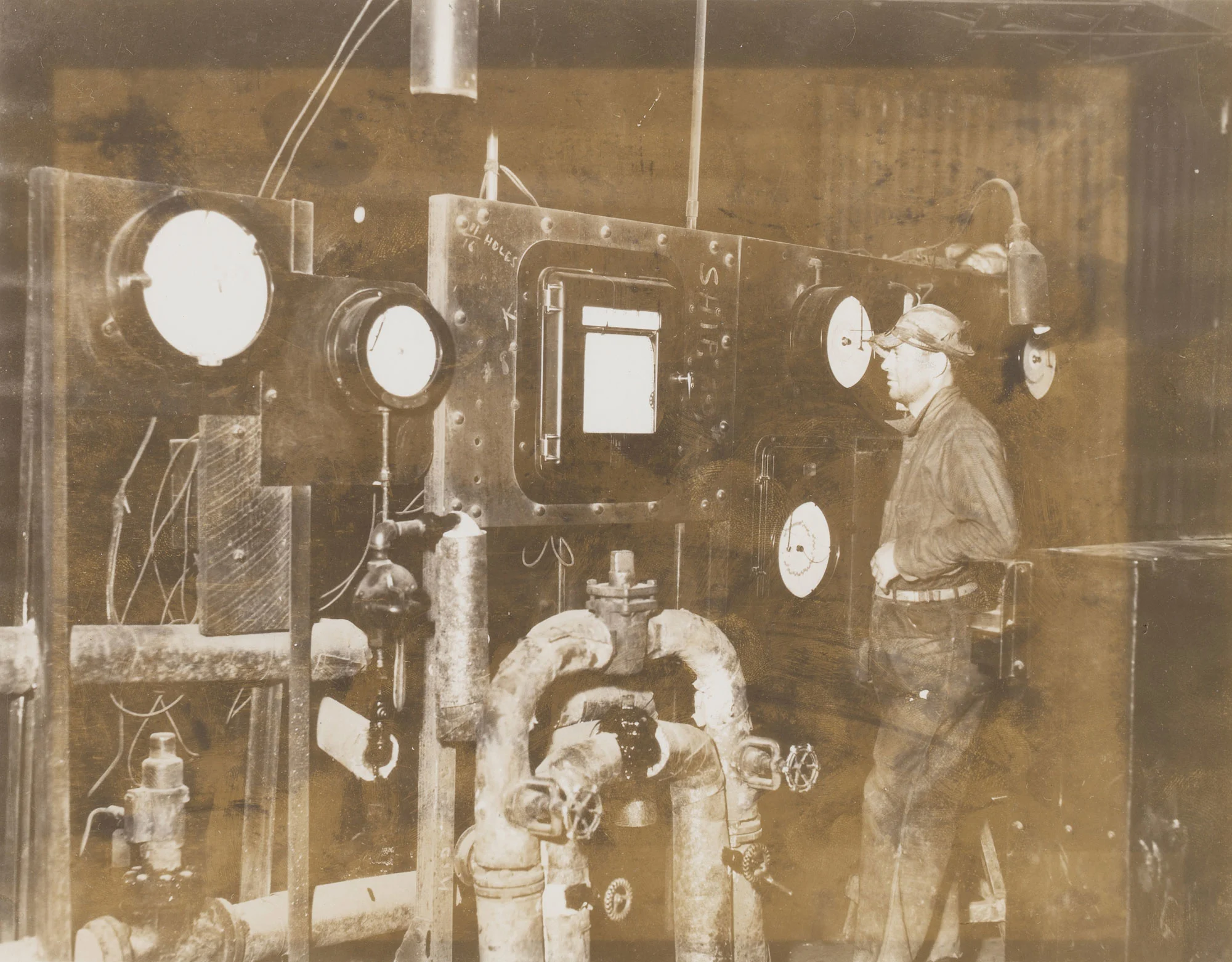

An employee is seen gazing into the "electric eye" temperature control device in following the progress of the heat in this furnace at U.S. Steel's Gary Steel Works, Gary, Indiana.

An employee in U.S. Steel's Gary Steel Works, Gary, Indiana, inspects the control dial of an "electric eye" to observe the temperature indications of a heat of steel in this open hearth furnace. (Shay's Photography)

The inside of the "electric eye" is shown in this view as it appears in an inactive open hearth furnace at S. Steel's Gary Steel Works, Gary, Indiana. (Shay's Photography)

How the inside end of the "electric eye" temperature control appears in active open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana, is shown is this view taken through the door of an active furnace. The terrific heat of the molten mass is indicated by the line of flame running horizontally across the picture just above the "eye" end. (Shay's Photography)

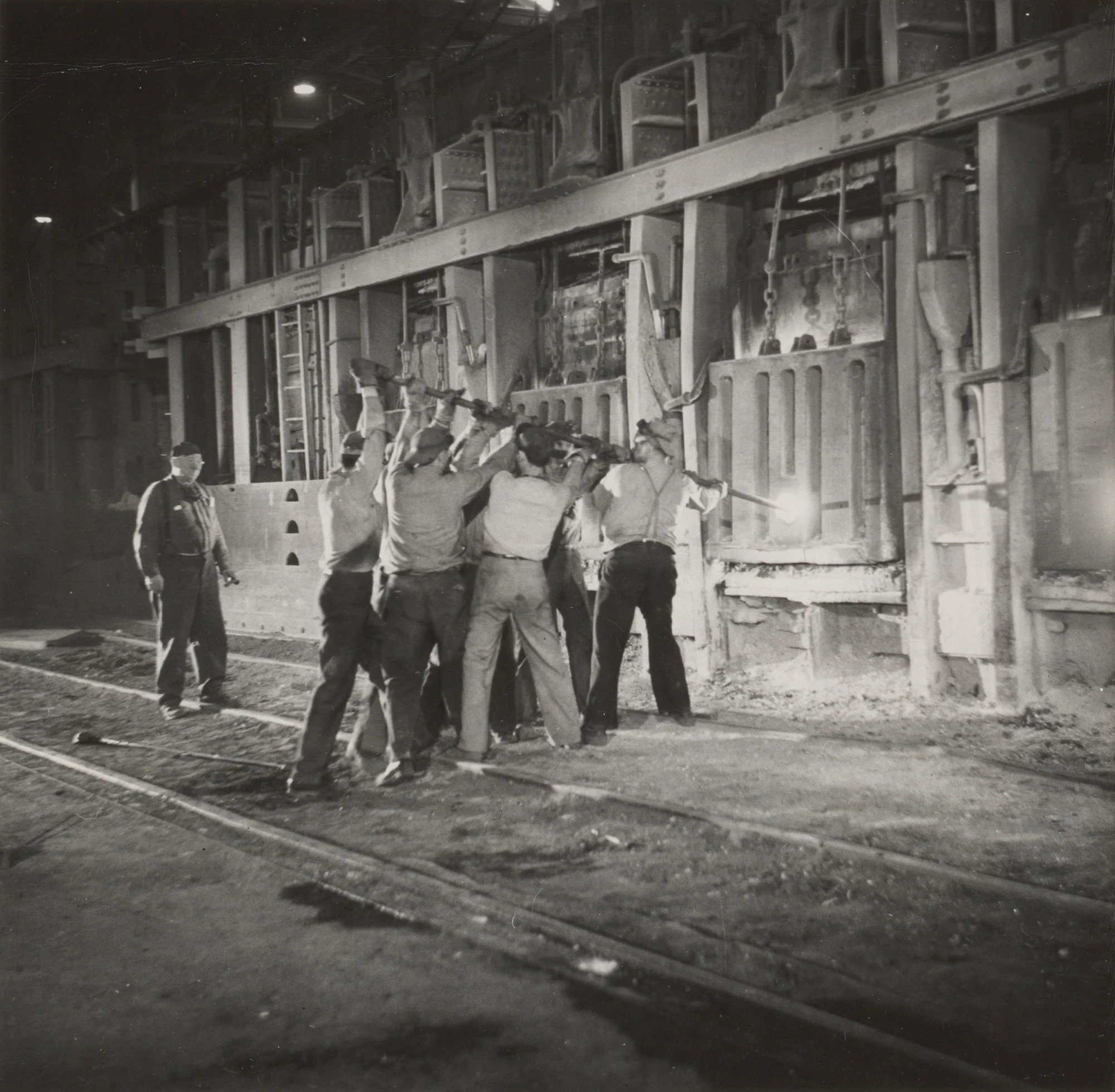

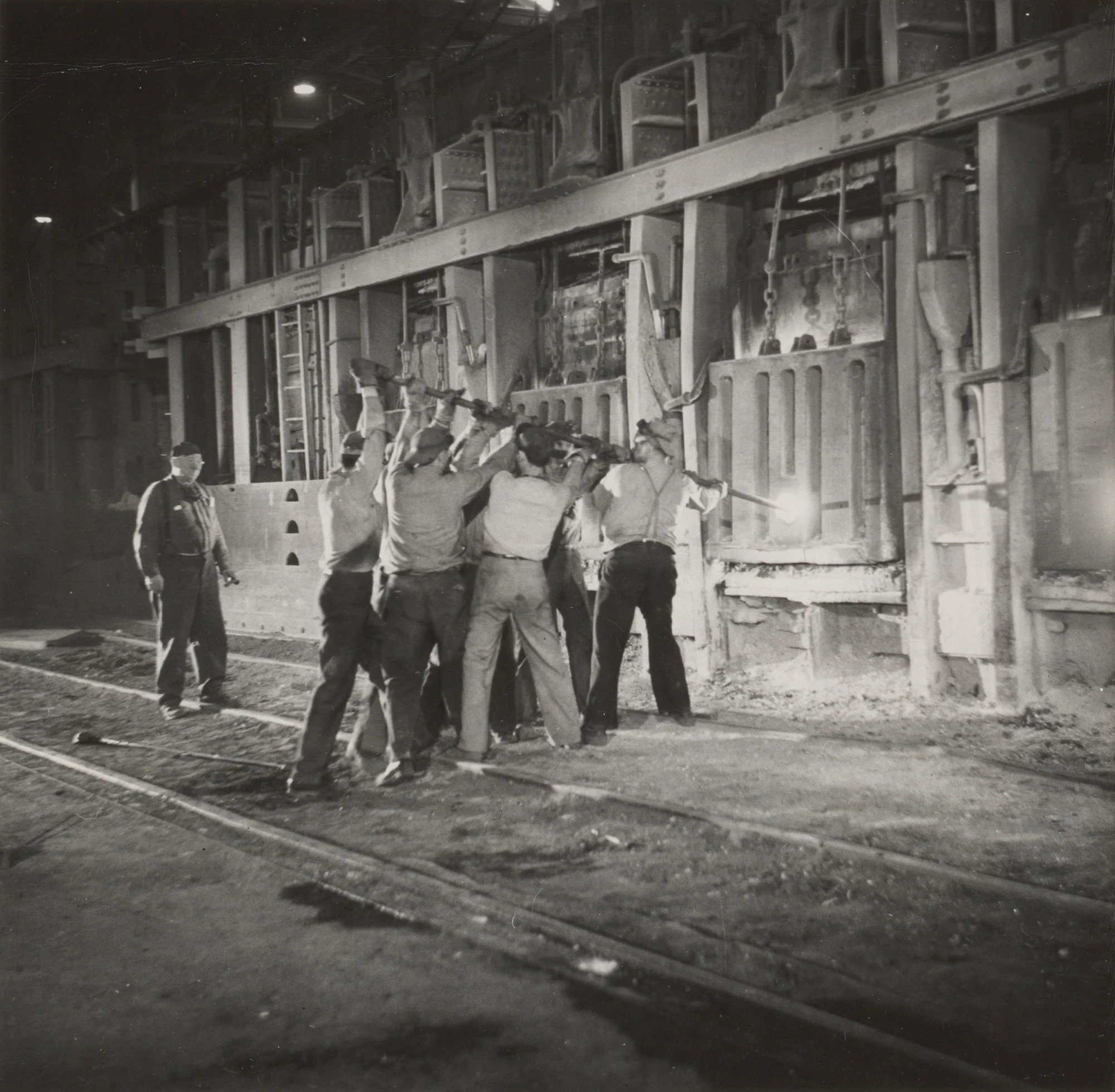

TAPPING TEAMWORK. Open hearth workers tap one of the furnaces at U.S. Steel's Gary Steel Works, Gary, Indiana in this scene from U.S. Steel's motion picture, "Unfinished Business." The long rod which they are poking through the hearth of the furnace opens the tap hole on the far side.

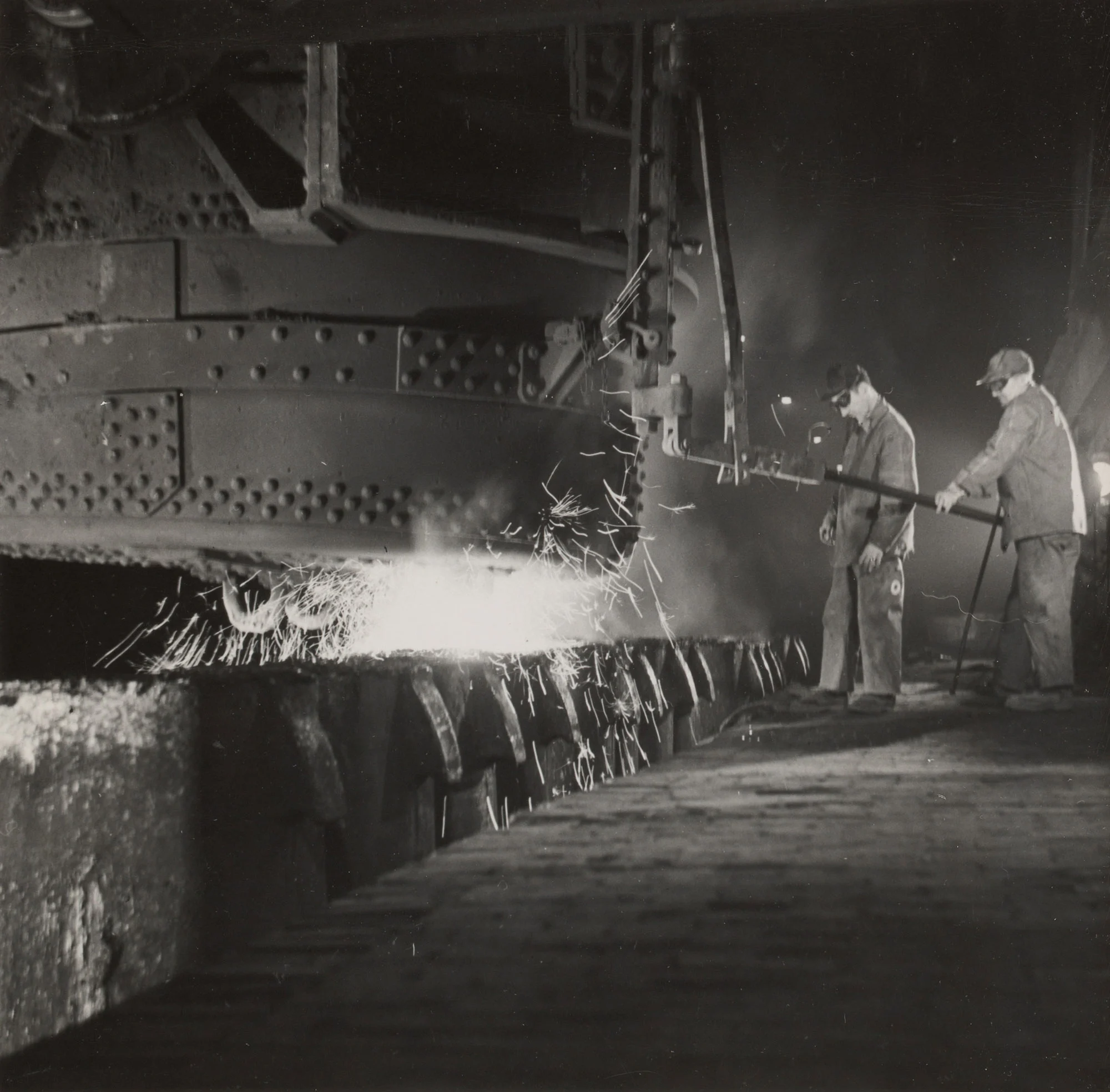

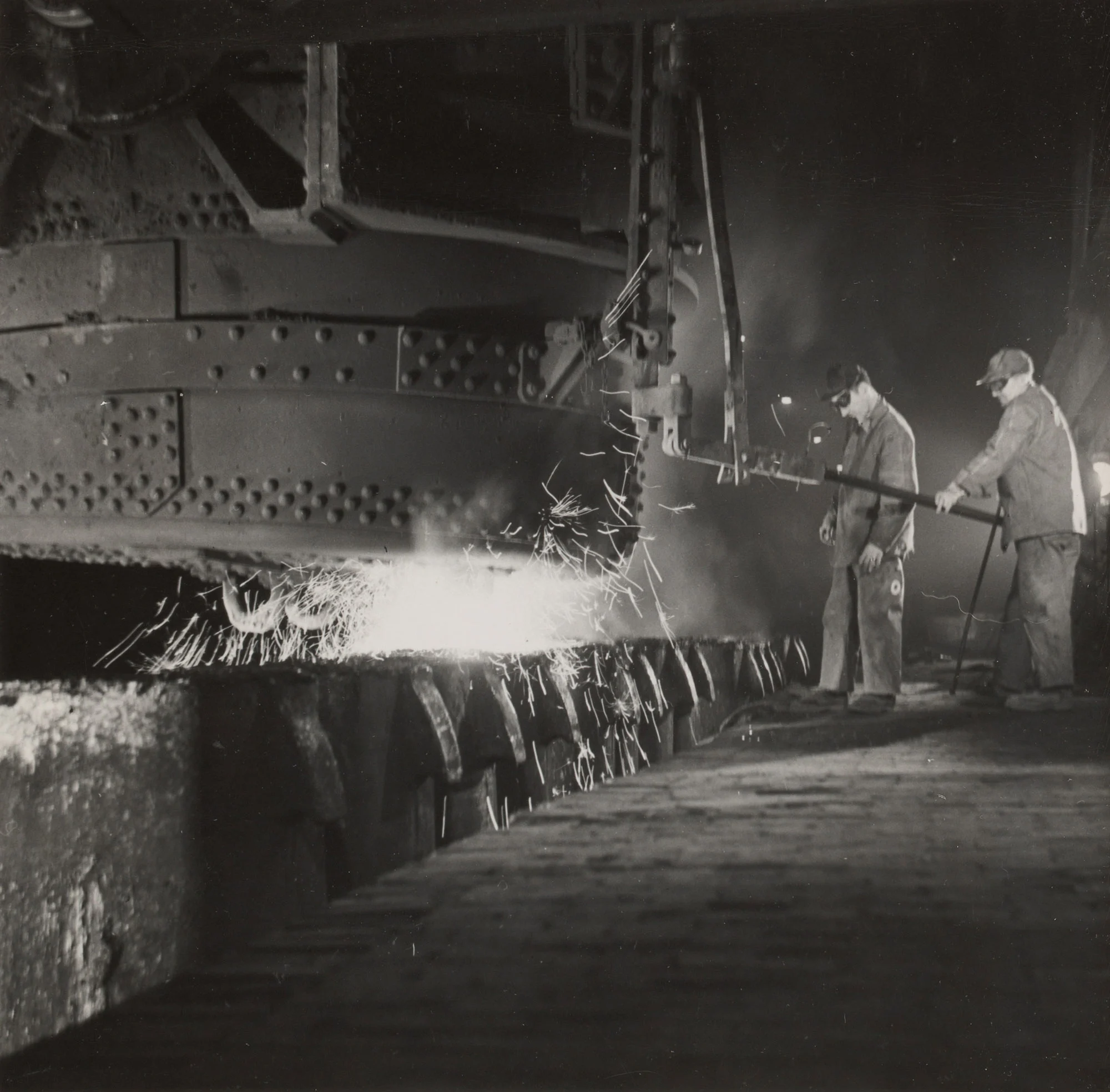

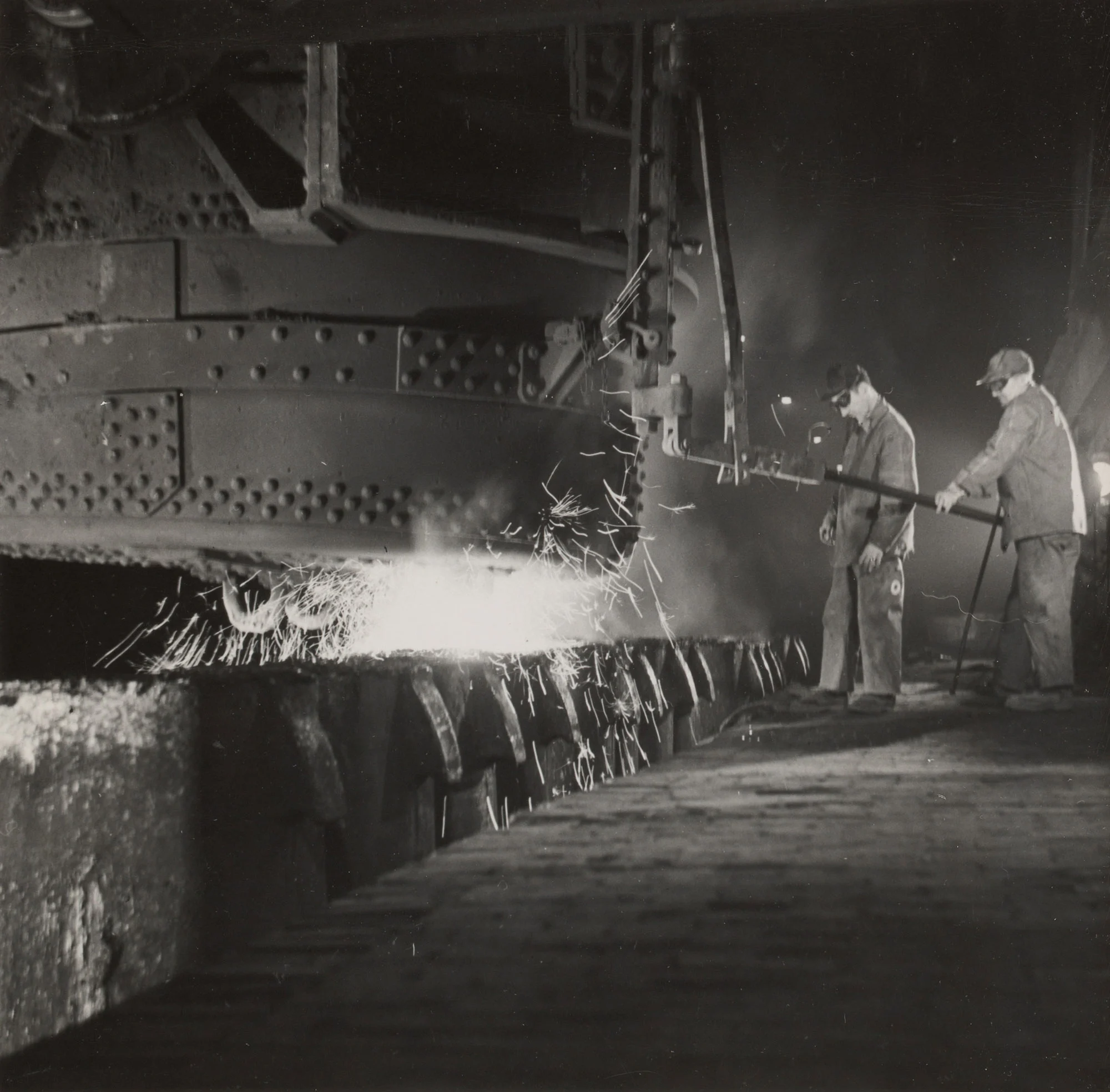

First helper burning out the "plug" preparatory to tapping this open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana. (Fred Korth, photographer)

Tapping an open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana. Heavier than slag, the molten steel flows from the furnace first, nearly filling the ladle. Slag follows next and is allowed to overflow into the slag thimble alongside.

INDUSTRIAL FIREWORKS. One of the highlights of U.S. Steel's new motion picture, "Unfinished Business," is this open hearth tapping scene at U.S. Steel's Gary Steel Works, Gary, Indiana.

100-tons of blast furnace iron being poured at the open hearths into transfer ladle at U.S. Steel's Gary Steel Works, Gary, Indiana. (Fred Korth, photographer)

TEAM OF TEEMERS. One of the dramatic highlights in U.S. Steel’s motion picture. "Unfinished Business," is this ingot teeming operation. In this operation at the number 4 open hearth shop of U.S. Steel’s Gary Steel Works, Gary, Indiana, the red hot Molten steel is teemed from the ladle into ingot molds.

A close-up of the steel pourer watching the stream of steel filling an ingot mold at U.S. Steel's Gary Steel Works, Gary Indiana. The stopper rod operating lever which he will use to cut off the stream is resting on the pouring platform at his feet. The crane operator who will move the ladle over each of the moulds can be seen in the crane operating cage just behind the steel ladle. (Fred Korth, photographer)

Ingot molds in transit at U.S. Steel's Gary Steel Works, Gary Indiana. (Robert Yarnall Richie, photographer)

Ingot of steel being lifted from soaking pits after it has been heated to the temperature necessary for subsequently rolling into rails at U.S. Steel's Gary Steel Works, Gary Indiana. (Fred Korth, photographer)

After reheating to uniform temperature throughout, ingots are withdrawn from the soaking pit in the 45-inch slabbing mill at U.S. Steel's Homestead District Works, Munhall, Pennsylvania. John Sitak, of 3320 Lincoln Avenue, West Mifflin, Pennsylvania, looks on. (Fritz Henle, photographer)

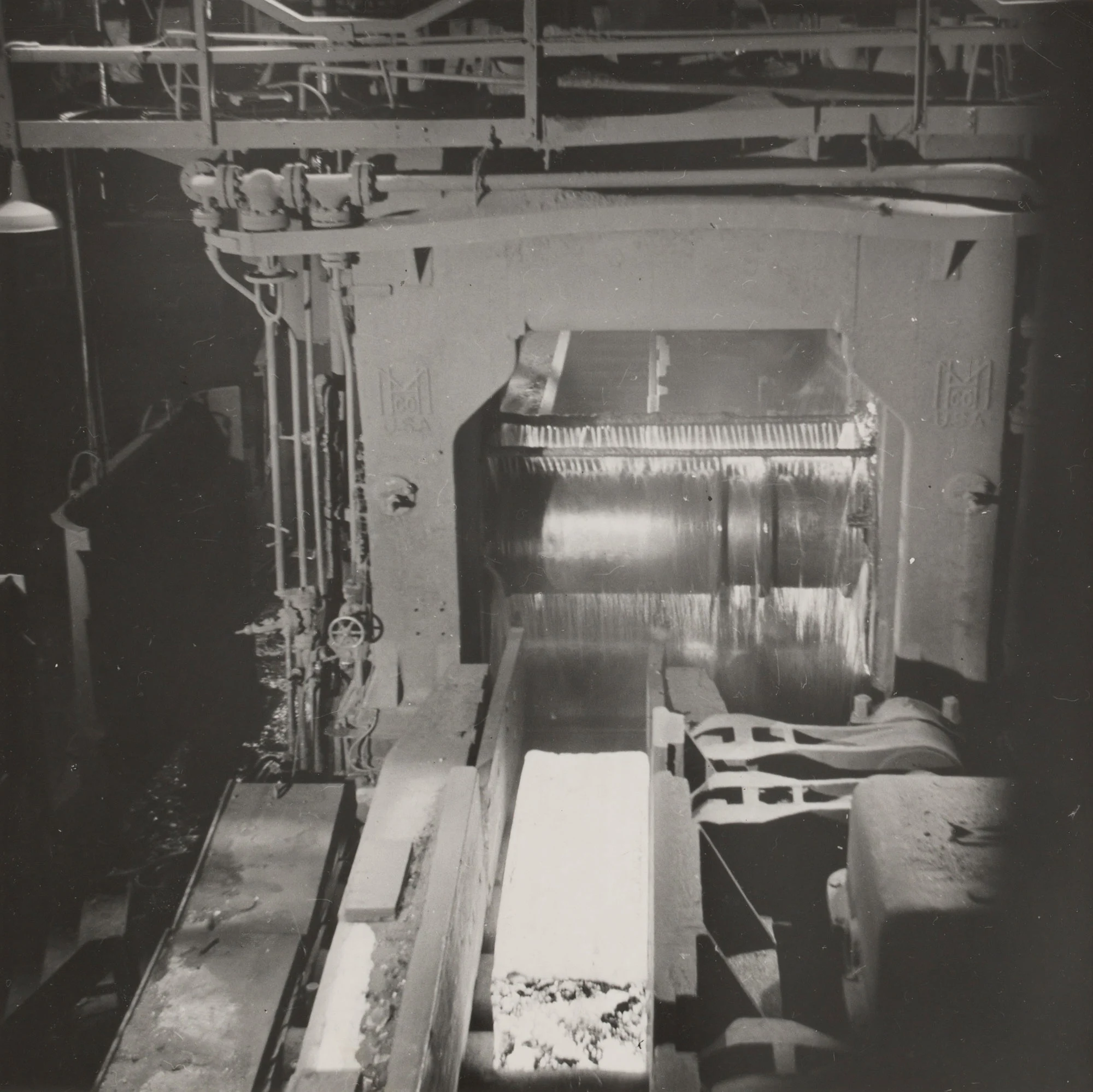

An ingot weighing approximately 12 tons is shown entering the rolls of the 44-inch blooming mill at U.S. Steel's Gary Steel Works, Gary, Indiana.

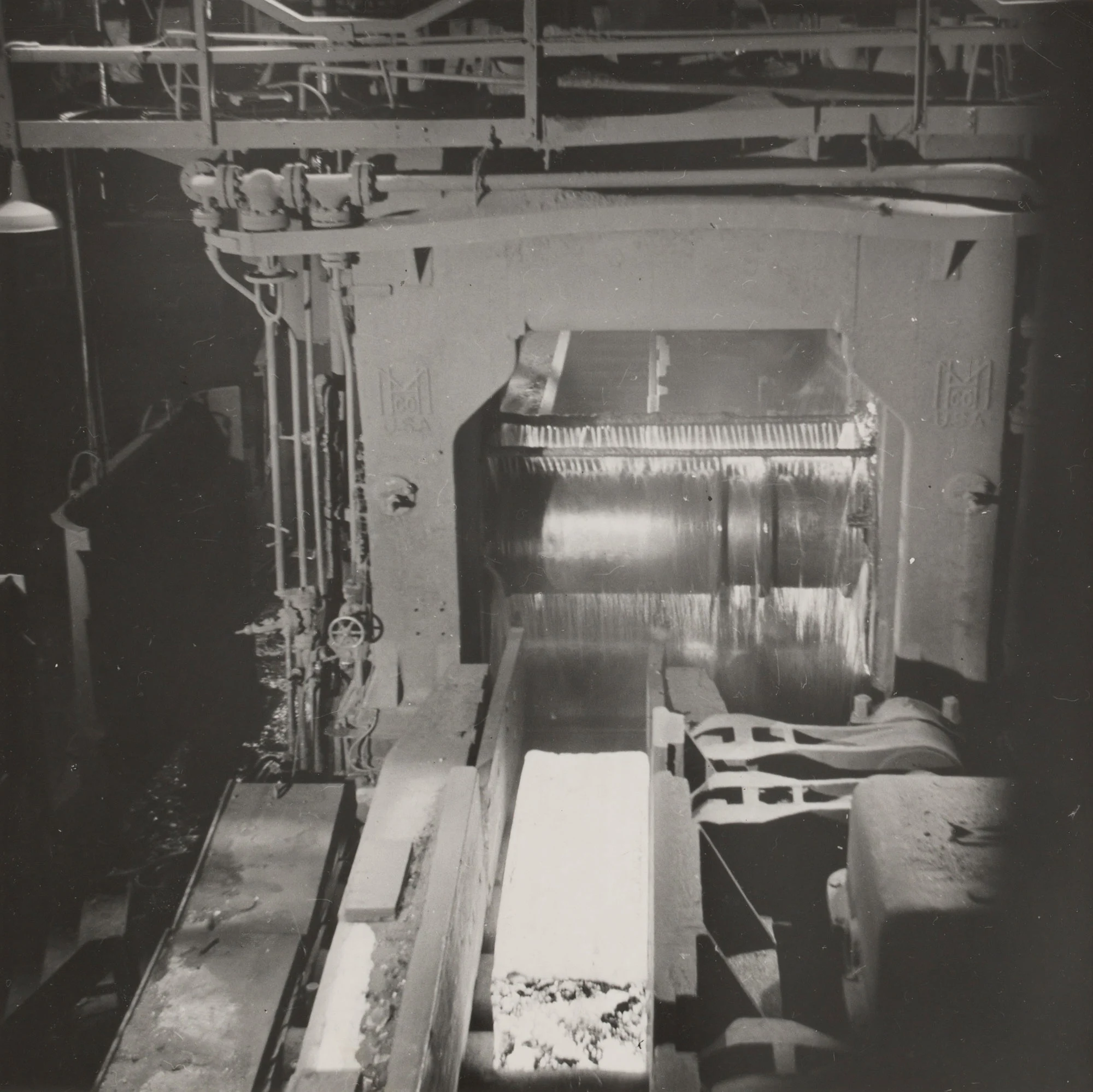

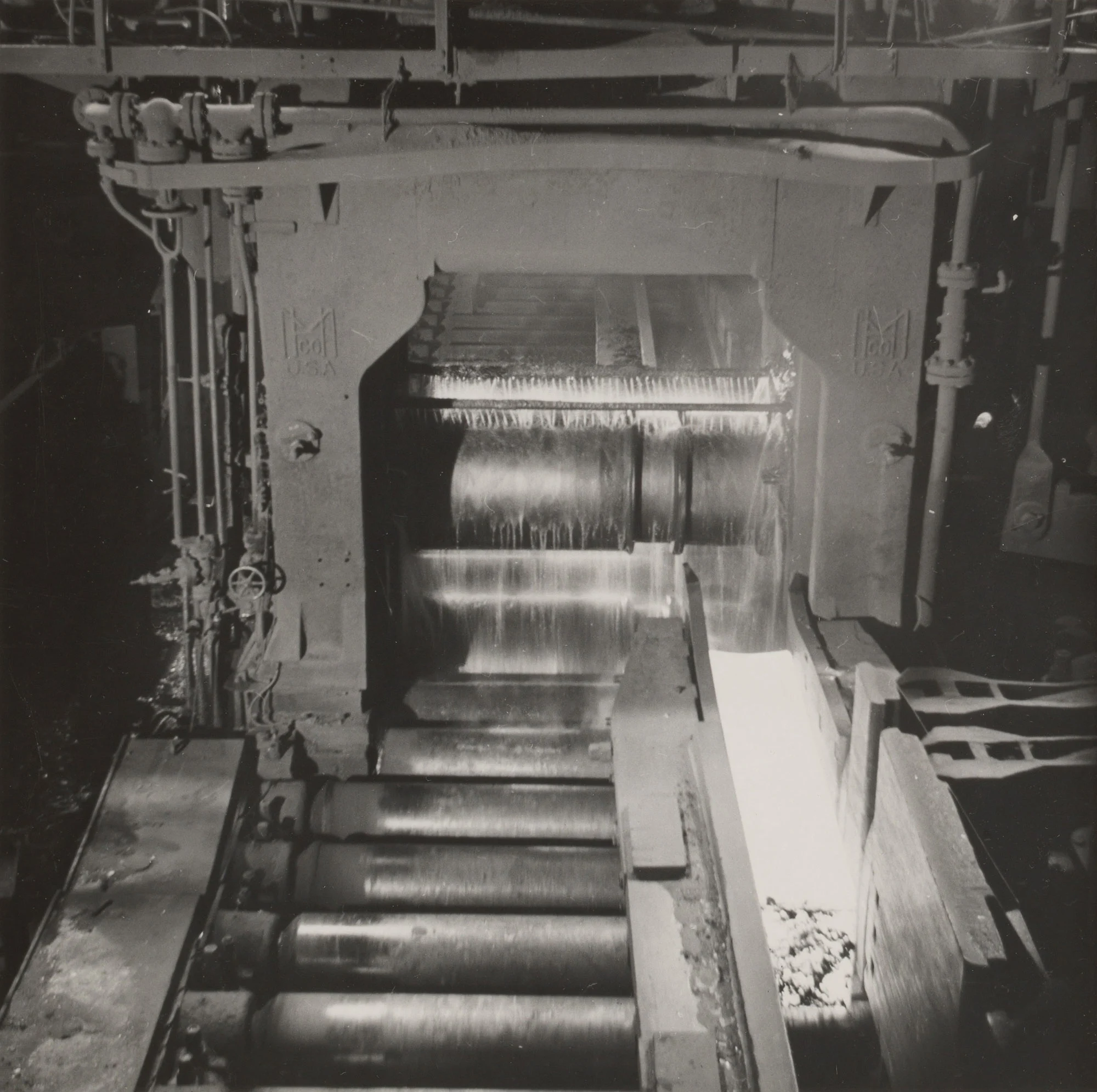

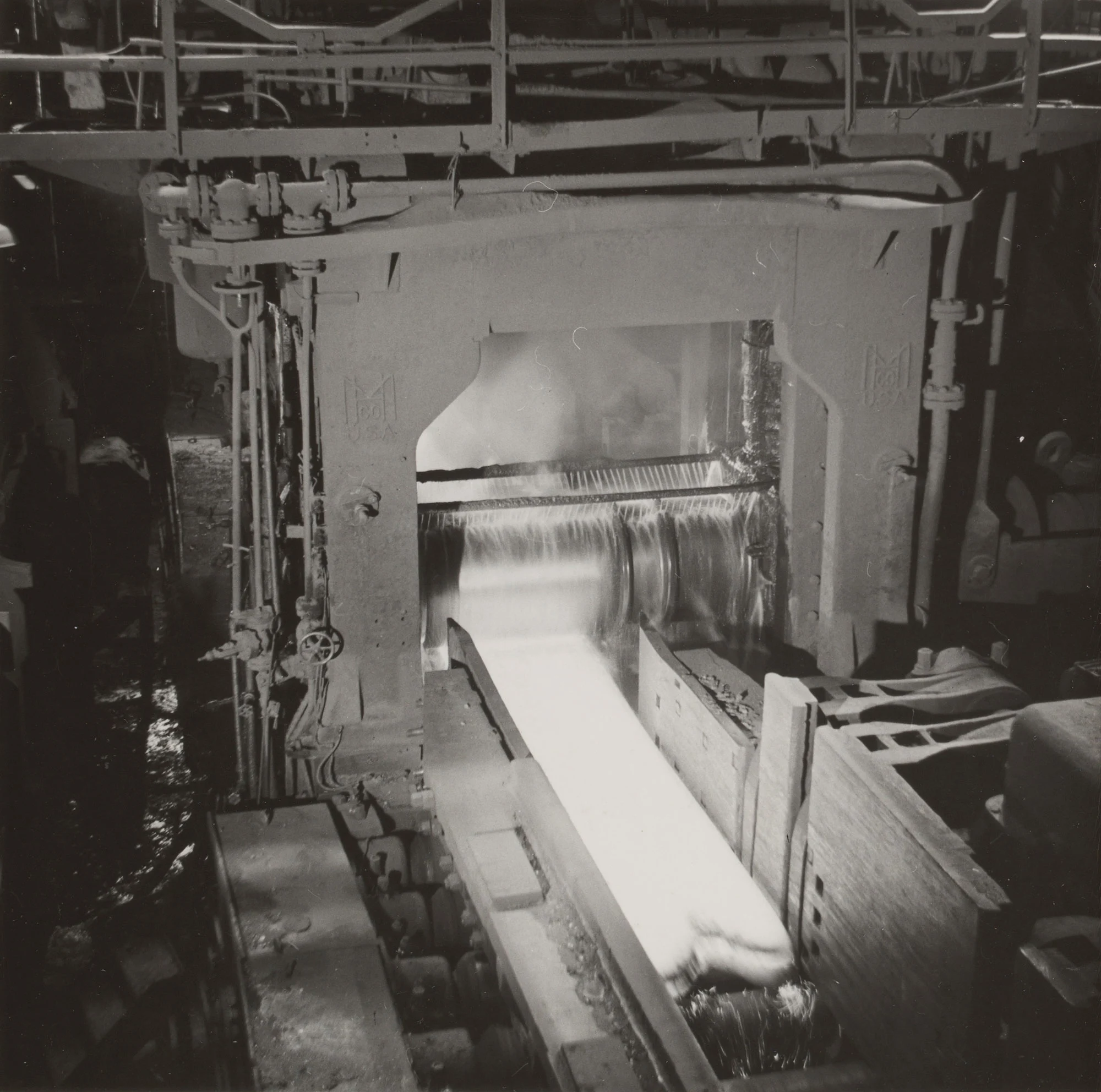

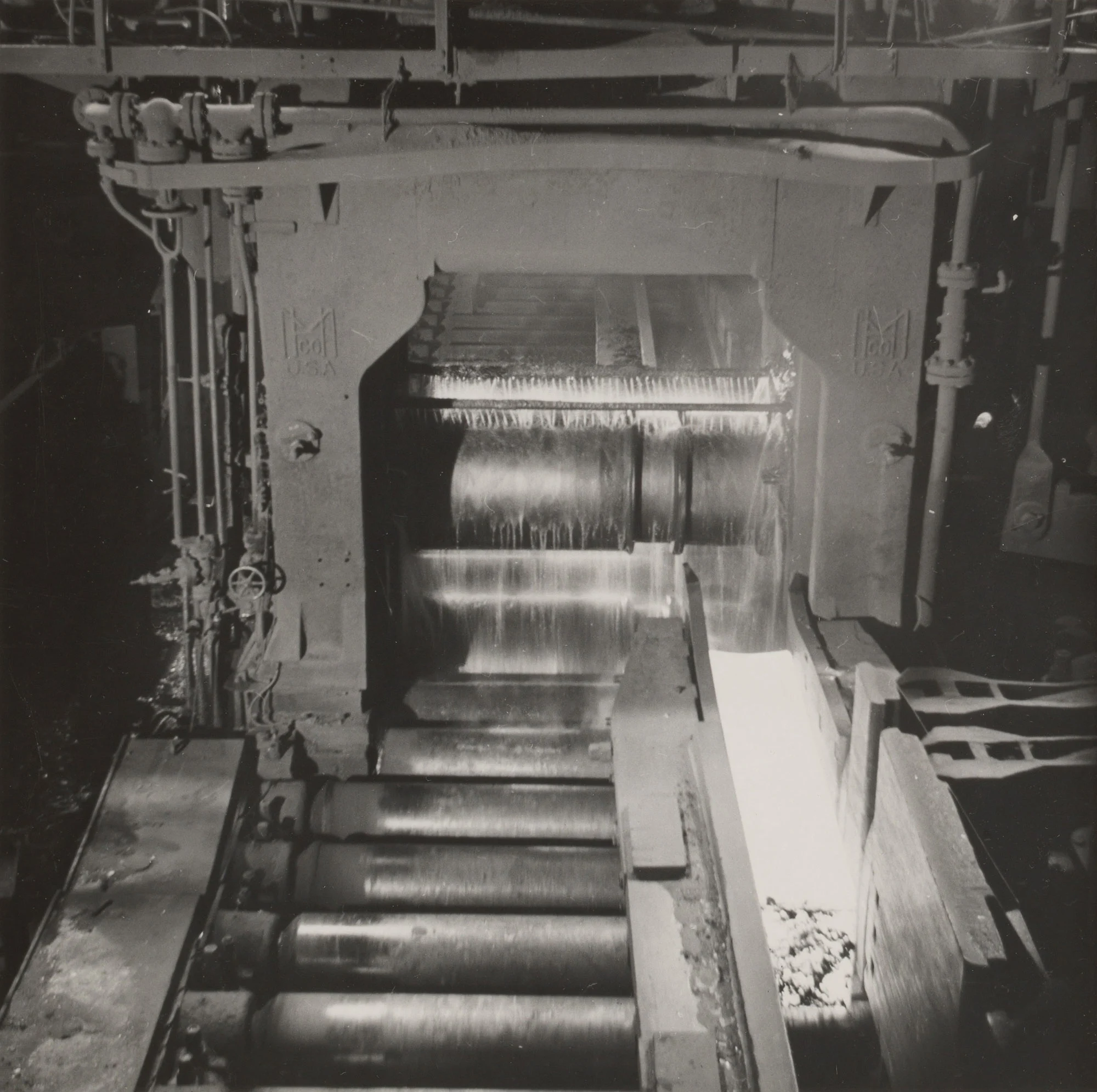

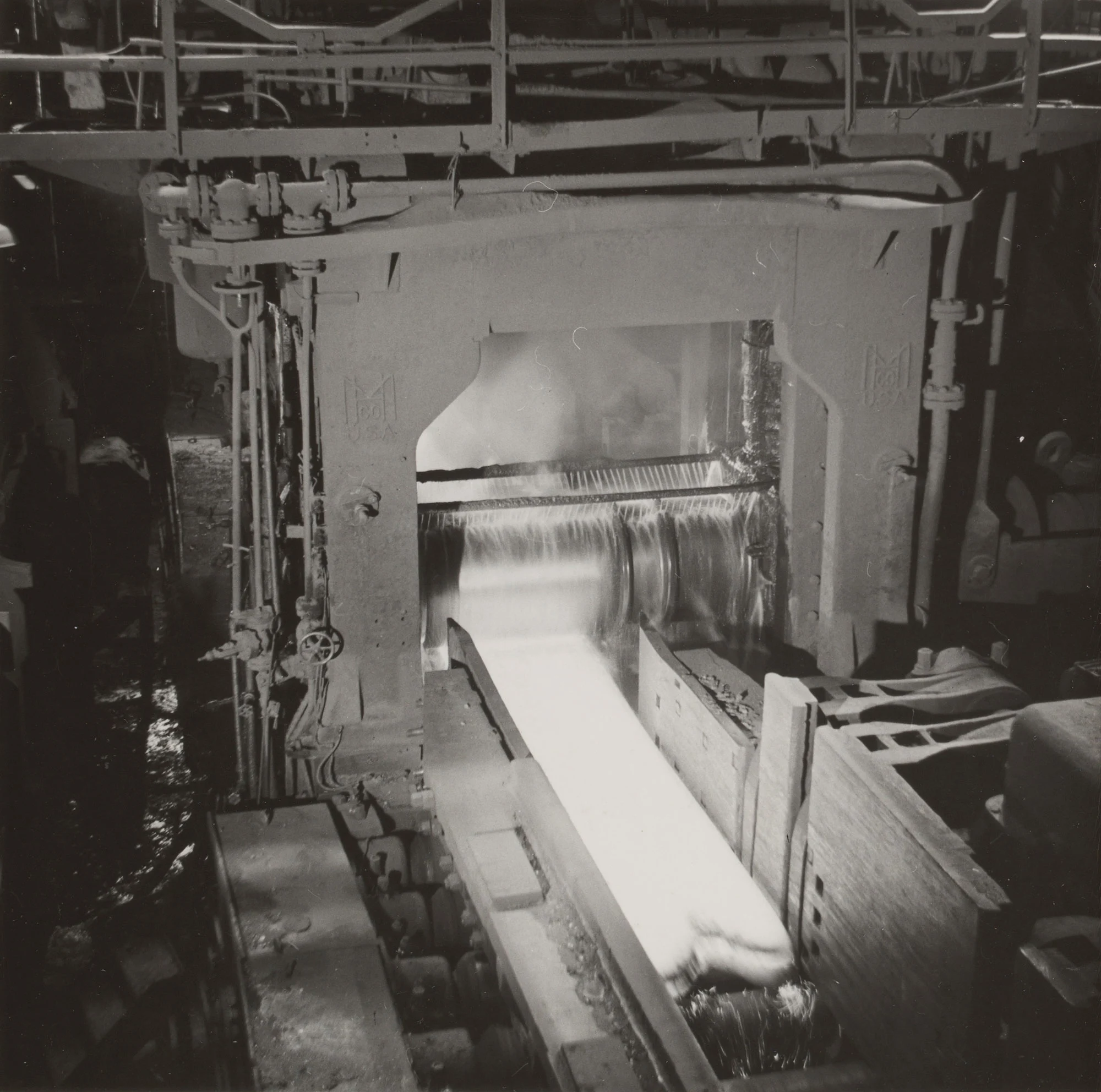

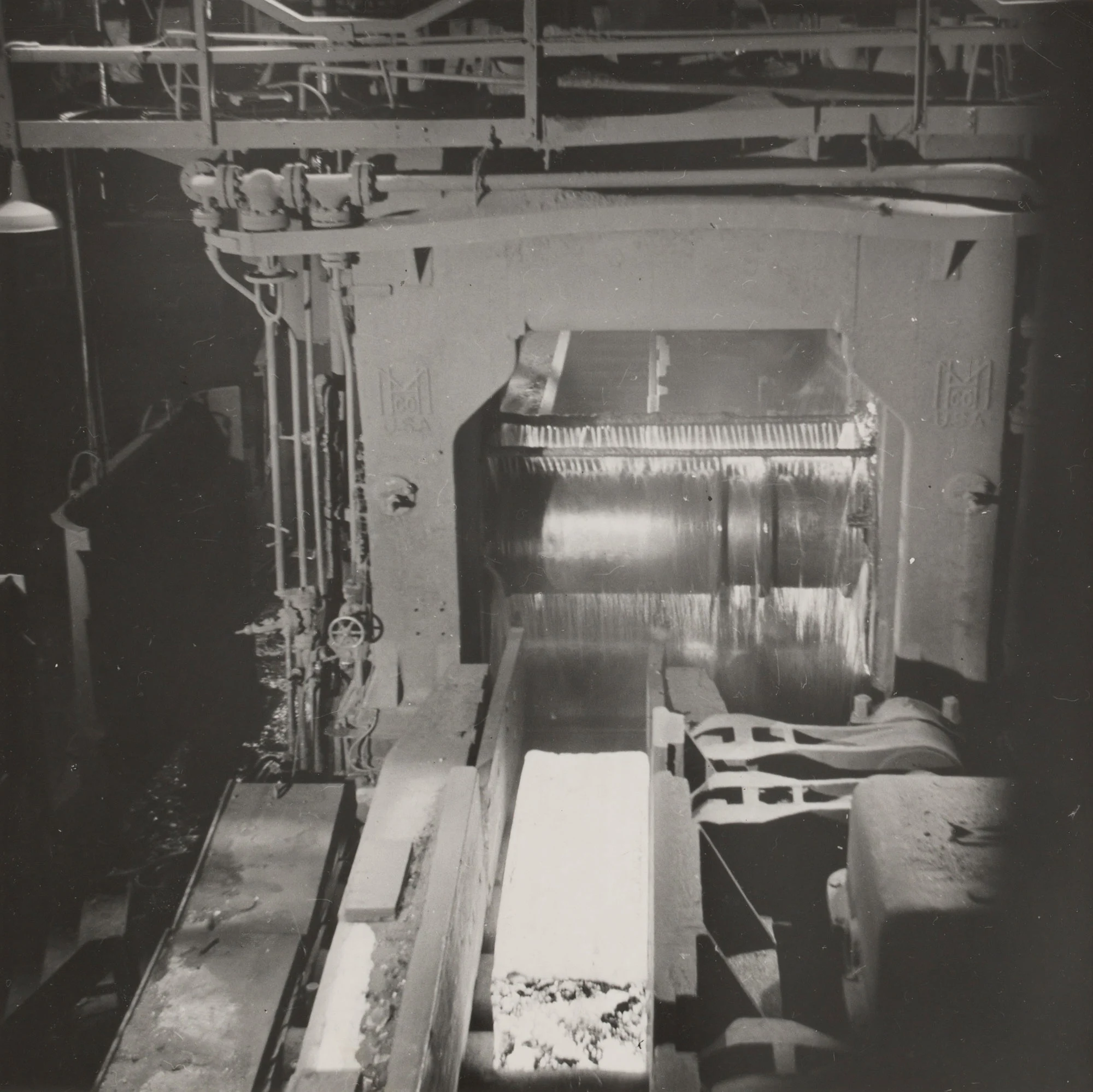

ANIMATION SEQUENCE background in U.S. Steel's new motion picture, "Unfinished Business," was this 44-inch blooming mill at U.S. Steel's Gary Steel Works, Gary, Indiana. This view shows the first of four successive stages in the rolling of an ingot down to a slab.

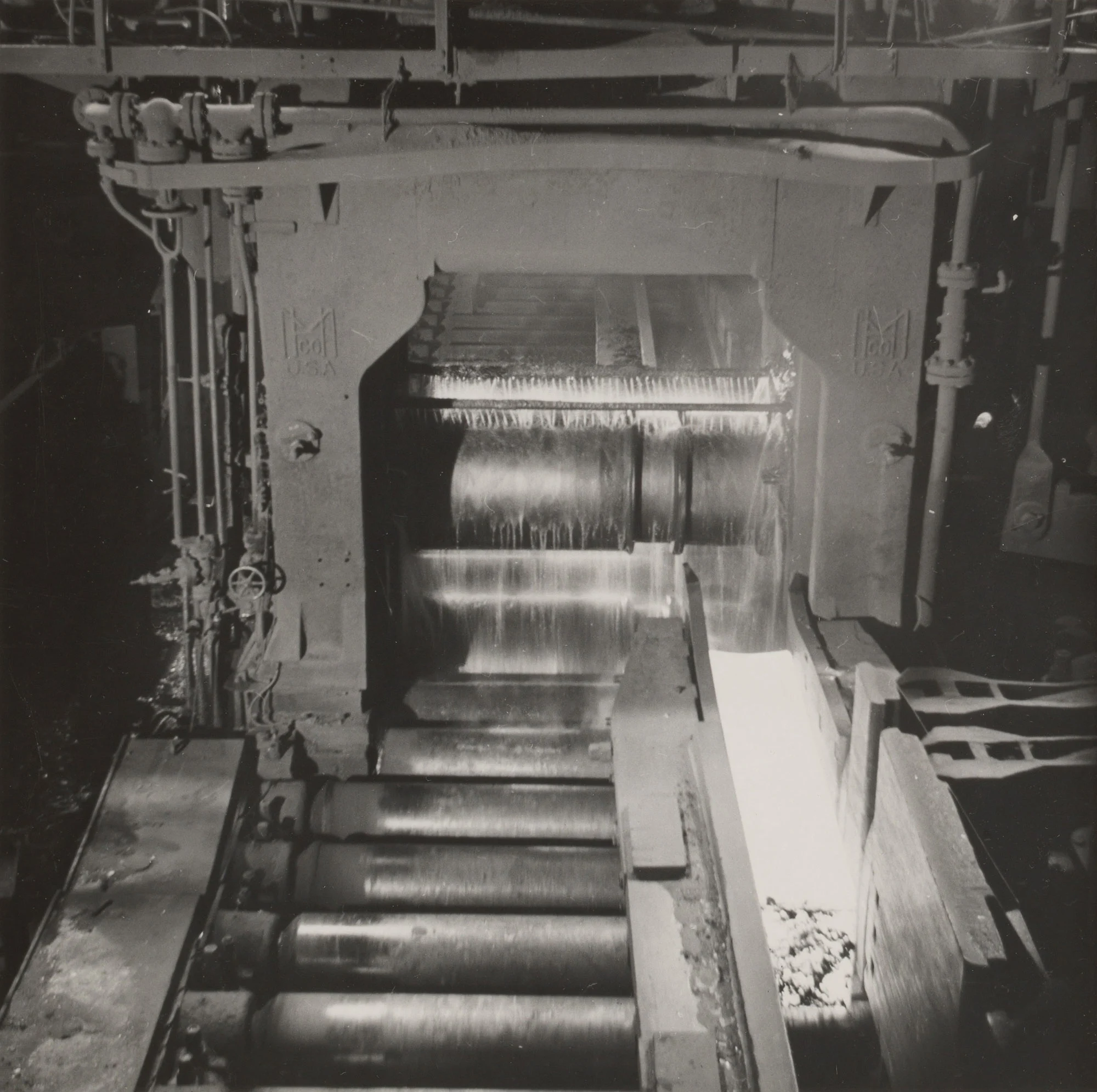

ANIMATION SEQUENCE background in U.S. Steel's new motion picture, "Unfinished Business," was this 44-inch blooming mill at U.S. Steel's Gary Steel Works, Gary, Indiana. This view shows the second of four successive stages in the rolling of an ingot down to a slab.

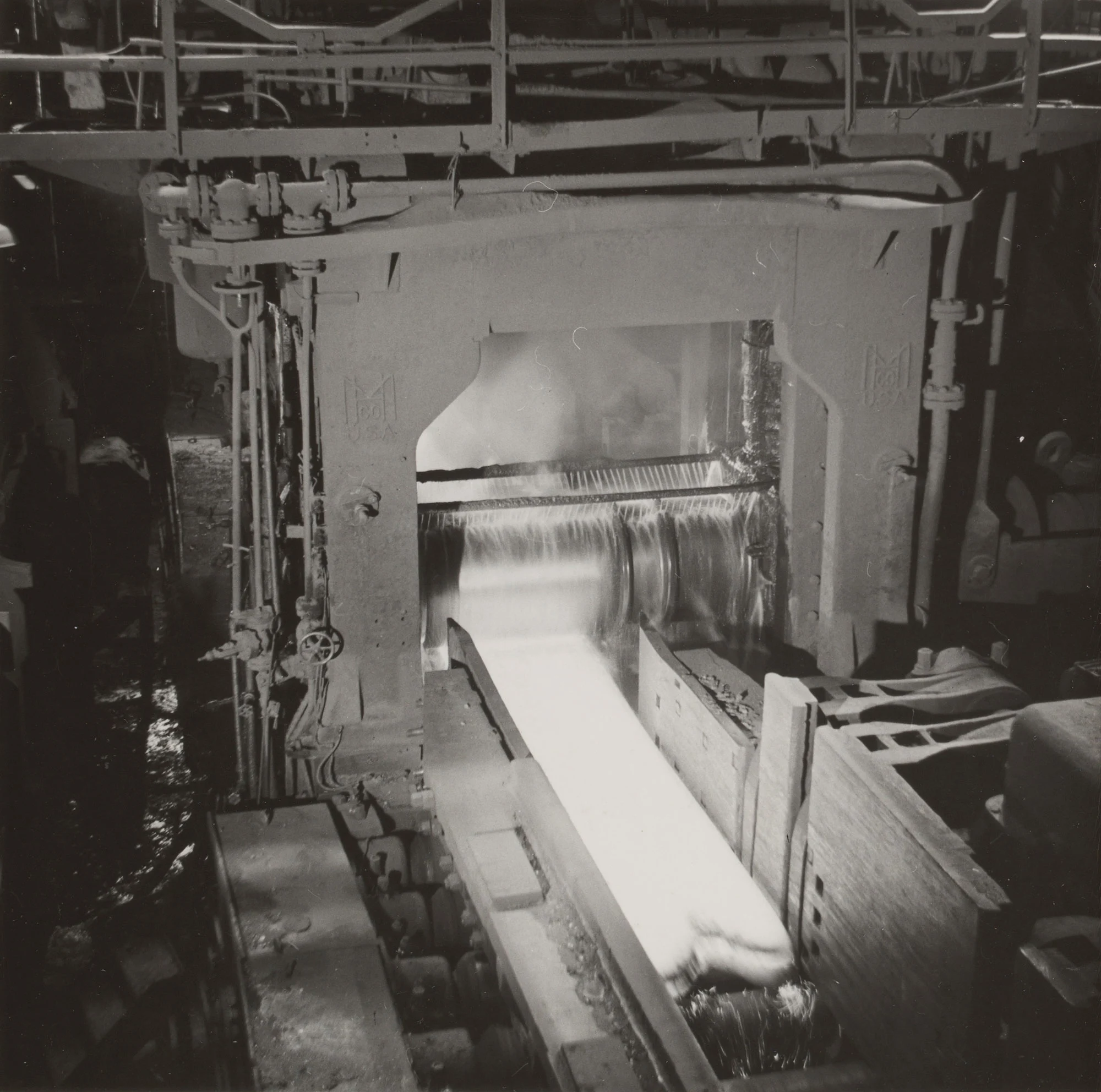

ANIMATION SEQUENCE background in U.S. Steel's new motion picture, "Unfinished Business," was this 44-inch blooming mill at U.S. Steel's Gary Steel Works, Gary, Indiana. This view shows the third of four successive stages in the rolling of an ingot down to a slab.

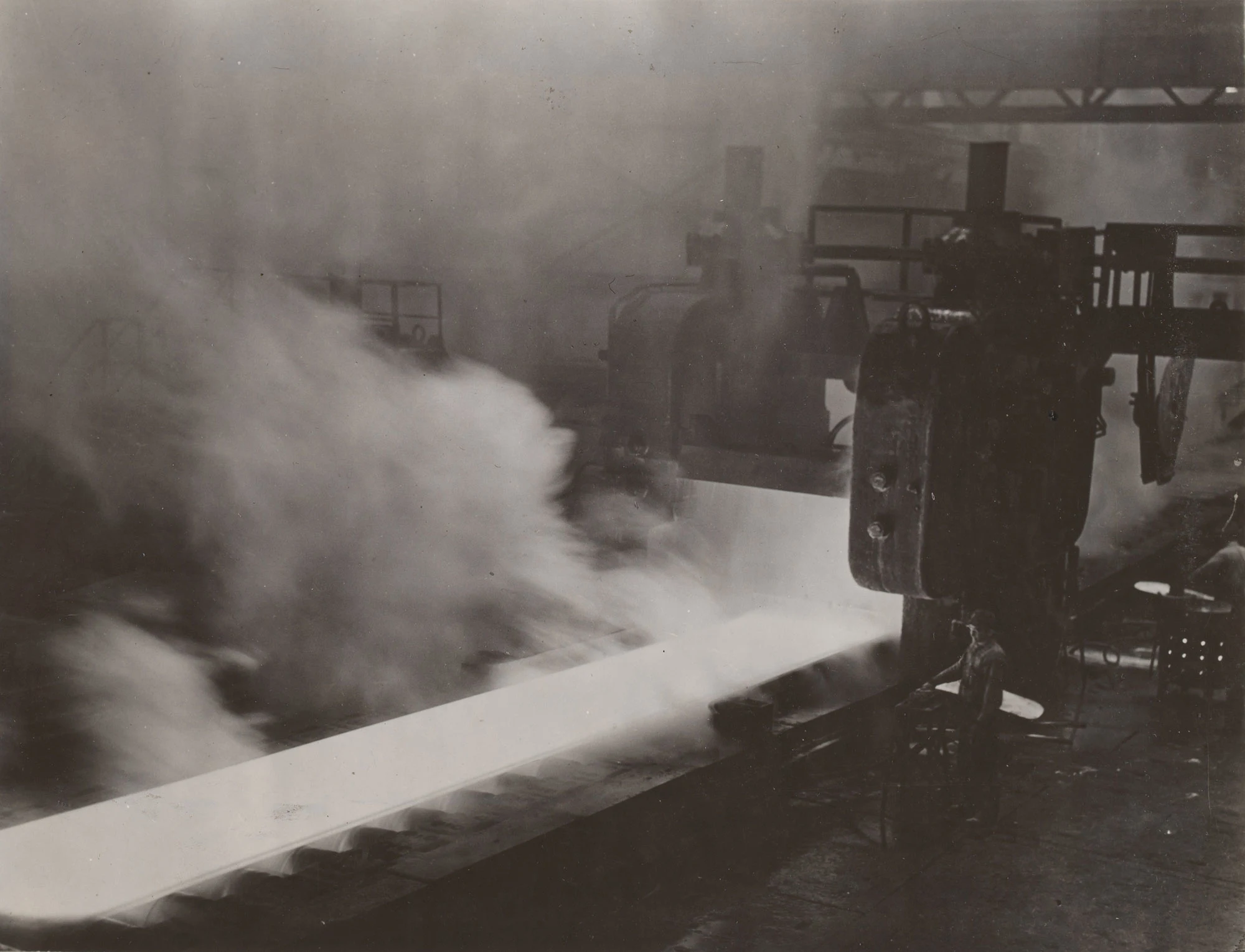

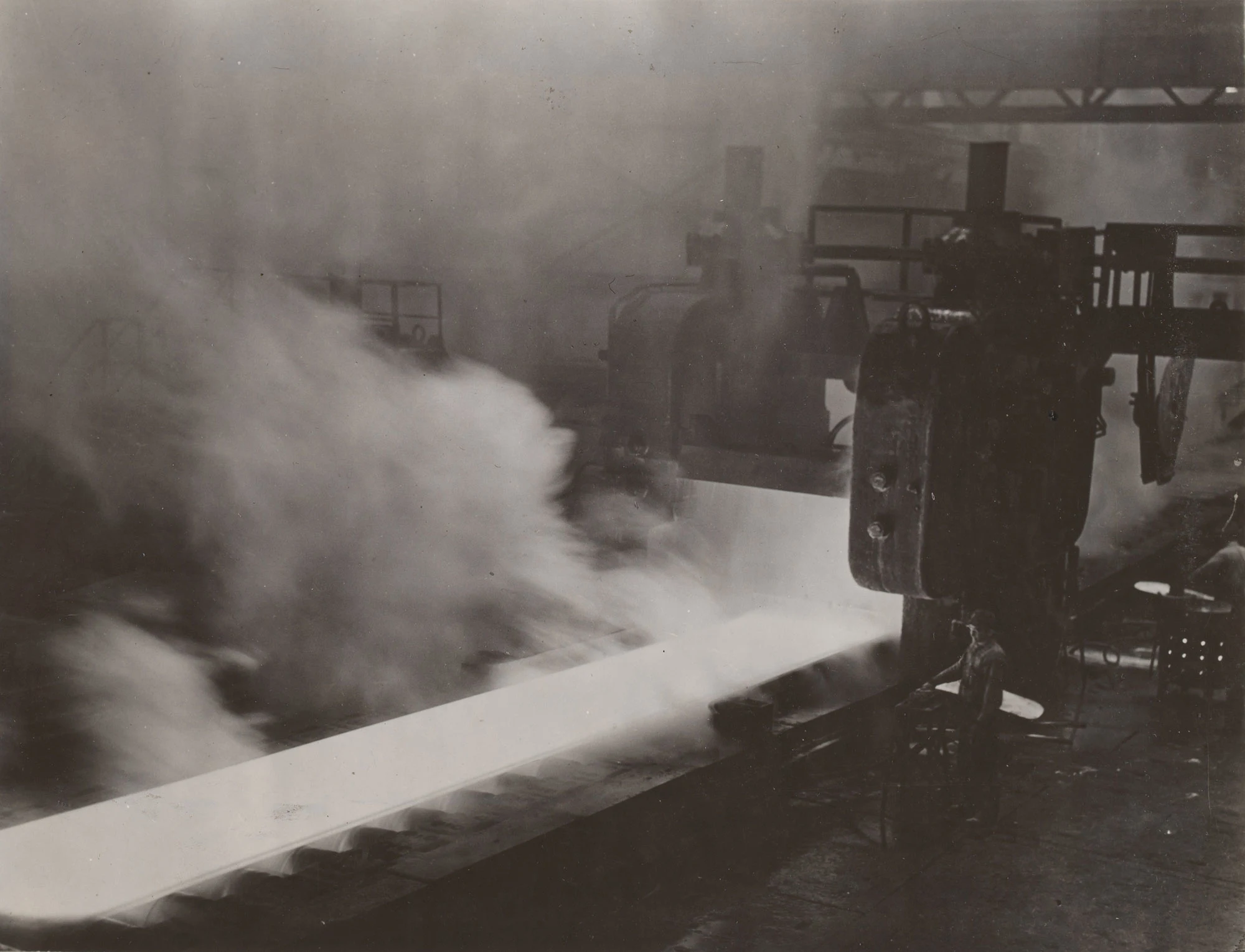

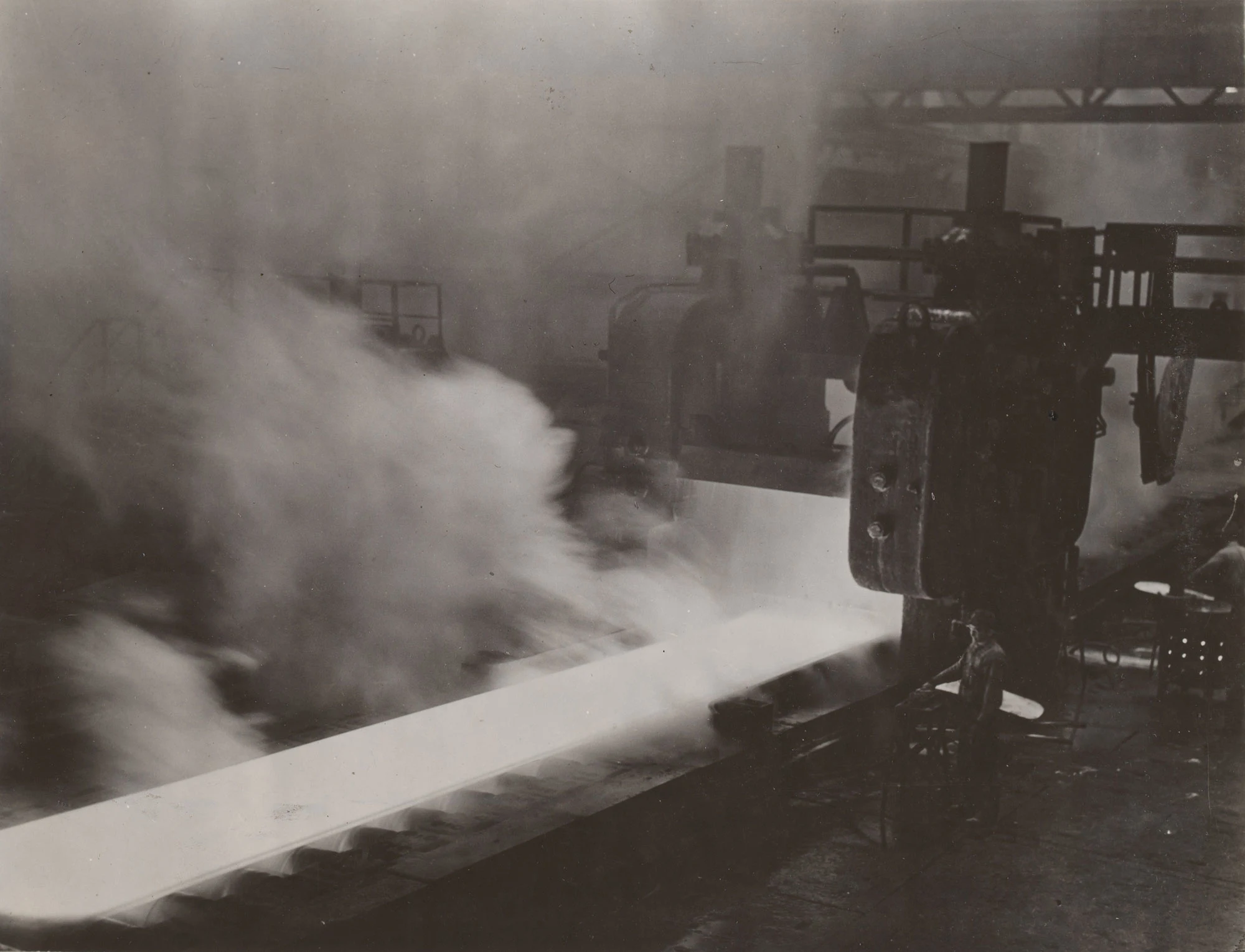

Steam caused by high pressure descaling water striking the hot plate enshrouds the mill at U.S. Steel's Gary Steel Works, Gary, Indiana. (Russell C. Aikins, photographer)

Shifting a red hot steel plate for another pass in the 160-inch plate mill of U.S. Steel's Gary Steel Works, Gary, Indiana. The second hooker seen with the rods are, left to right, Chester P. Kalita, 1651 west 39th Street, Gary, and Victor M. Malis, 1929 Cleveland Street, Gary. This is one of the largest mills in the country engaged in making steel plates for industrial purposes. They are used in structural work by railroads as well as in the building of dams and ships and similar projects.

After cold rolling and shearing to size, sheets are conveyed to the heat treating furnaces where they are heat treated at 1300 degrees Fahrenheit for a specified time, usually about 50 hours. This treatment releases the strains set up in the steel during cold working and imparts ductility and softness. Sheets are placed in piles, covered with annealing boxes and charged into furnaces like this one at U.S. Steel's Gary Steel Works, Gary, Indiana. Temperature is governed by Prometric control. (Shay's Photography)

A five-ton ingot comes out of the second stand of rolls in the 40-inch billet mill at U.S. Steel's Gary Steel Works, Gary, Indiana. The white hot ingot becomes longer and the cross section smaller as it passes through successive stands of rolls, which exert a heavy squeezing pressure. At the left a mill oiler is seen lubricating the table rolls in the line shaft hears. He is Harry C. Countzmar of 2504 Madison Street, Gary.

Billet mill operations, where the intermediate step is taken between the furnaces and the finishing process in the merchant mill at U.S. Steel's Gary Steel Works, Gary, Indiana.

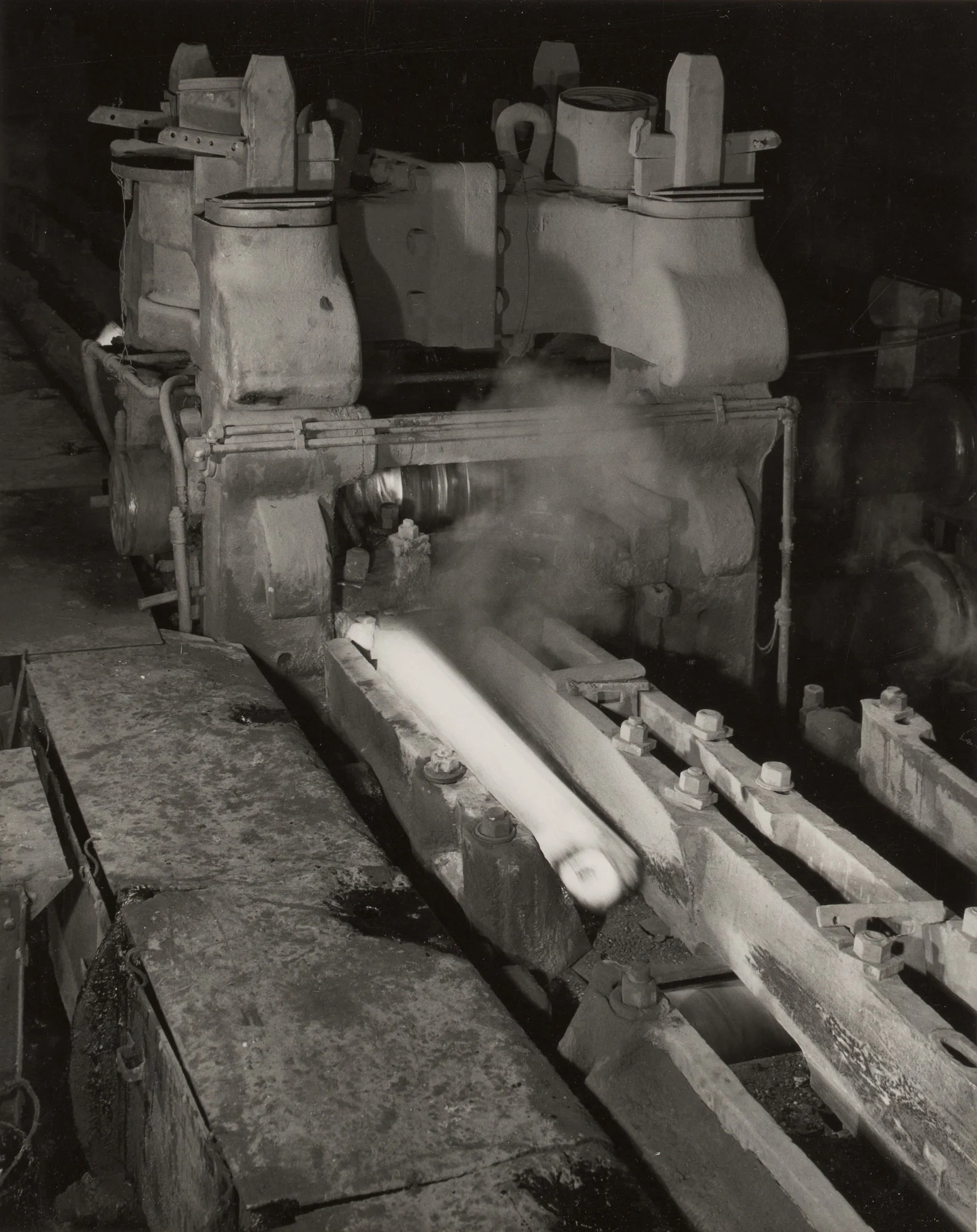

White hot steel comes out of the second stand in the 32-inch billet mill of U.S. Steel's Gary Steel Works, Gary, Indiana. Starting as a five ton ingot, the steel passed through stands of the 40-inch mill and then into the rolls of the 23-inch mill. Each successive stand of rolls squeezes the steel to greater length and smaller cross section. The Gary Works, which is the largest steel mill in the world, employs about 20,000 persons and is located on a 1440 acre site.

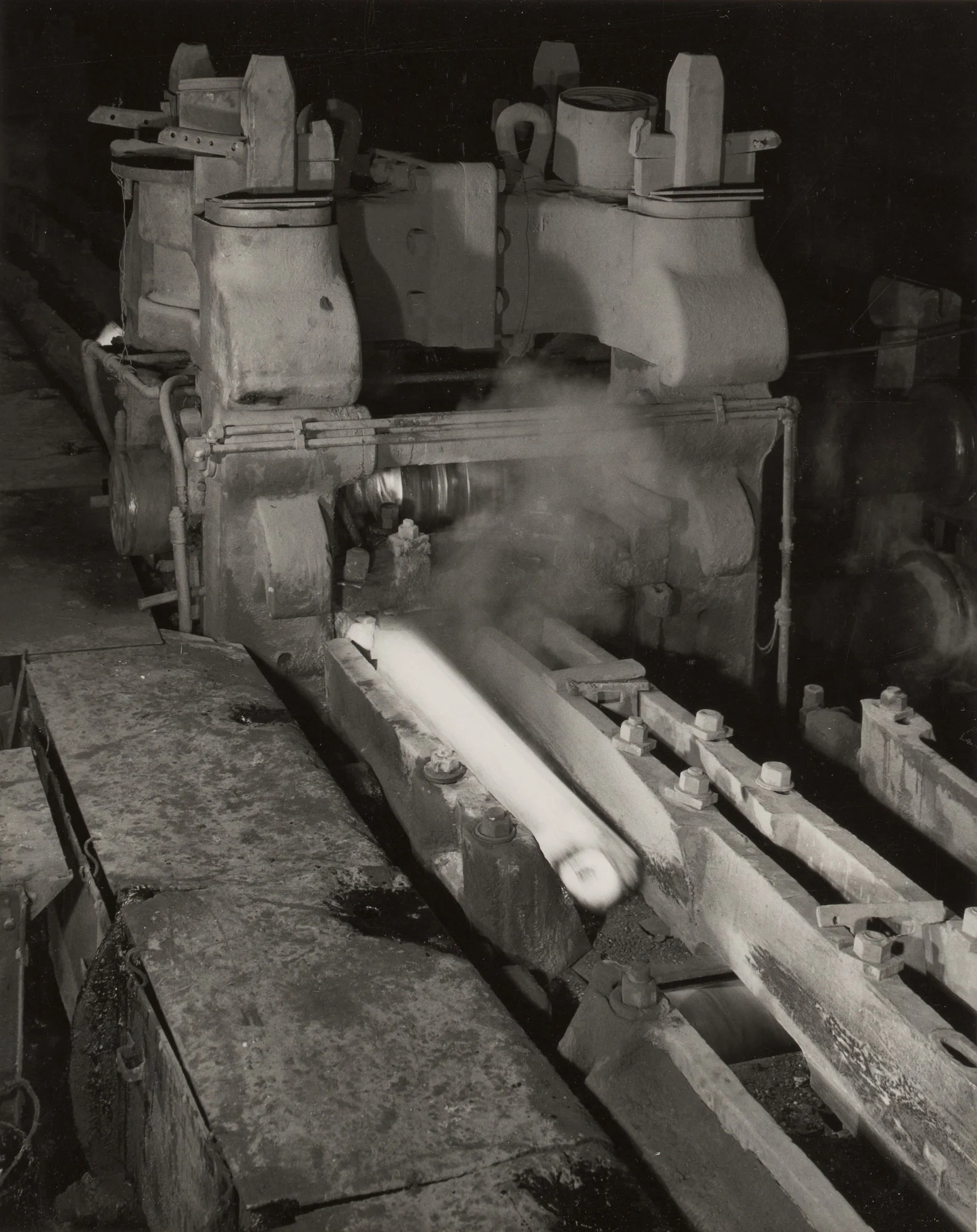

A white hot billet comes out of the 24-inch continuous mill in U.S. Steel’s Gary Steel Works, Gary, Indiana. The Billet is reduced to this size after starting in the rolls as a five ton ingot. It is seen here after having passed through first the 40-inch billet mill rolls, then those of the 32-inch mill and then the 24-inch mill. This is but one phase of operation in the largest steel mill in the world, the Gary Works, which is built on a 1440 acre site and employs about 20,000 persons.

An interior view of the rail mill at U.S. Steel's Gary Steel Works, Gary, Indiana. Various intermediate stages involved in the rolling of an ingot into rails is shown in this photograph.

Sparks fly ceiling-ward as the hot saws cut the rails into 39-foot sections at U.S. Steel's Gary Steel Works, Gary, Indiana.

Sparks fly ceiling-ward as the hot saws cut the rails into 39-foot sections at U.S. Steel's Gary Steel Works, Gary, Indiana.

Gauging the bolt holes in the new rails at the rail mill of U.S. Steel's Gary Steel Works, Gary, Indiana. The check is being made by Herbert E. Tilden, final Inspector of rails, of 2560 Monnier Road, Gary. In his left hand, partly hidden from view, is a gauge which determines if each hole is the proper distance from the base of the rail. In his right hand, he holds a gauge which shows whether or not the holes are the right distance apart and from the end of the rail.

Nick and break test for rails shown being made in the rail mill at U.S. Steel's Gary Steel Works, Gary, Indiana. A nick is cut in a section of rail. It is placed under the hydraulic hammer seen here and a gag maul held with an edge in the nick. The hammer exerts 1200 pounds of pressure on the flat top of the maul, which breaks the rail. Inspection of the segments determines if the steel is sound. Holding the maul handle is Michael E. Roll, mill inspector of 4782 Cleveland Street, Gary.

General view of a section of the wheel mill of U.S. Steel's Gary Steel Works, Gary, Indiana, where wrought steel wheels are made. Blocks to form a wheel of the desired weight and dimensions are cut from round blooms, preheated, and then forged into a wheel blank in a press. The bore is punched out and the blank after being reheated, is sent to the wheel rolling mill for further shaping. The wheel is later machined to meet specifications.

A red hot wheel block is taken from a reheating furnace preparatory to being forged into a freight car wheel in the wheel mill of U.S. Steel's Gary Steel Works, Gary, Indiana. The block weighs 930 pounds. Signaling the operator of the "claw" crane is Peter Chacharis, general maintenance foreman of the wheel mill, 316 Monroe Street, Gary. This is but one phase of operations in the Gary Works, which is the largest steel mill in the world.

Removing a red hot freight car wheel from a die where it just has been shaped by 10,000 tons of hydraulic pressure in the wheel mill at U.S. Steel's Gary Steel Works, Gary, Indiana. The wheel is 28 inches in diameter. Seen at the right blowing the scale out of the lower die with compressed air is Rudolph C. Krieger, pressman, of 725 Virginia Street, Gary. The Gary Works is the largest steel mill in the world. It employs about 20,000 persons and is located on a 1440 acre site.

Louis K. Soteros, conning press operator, shaping hub and plate of hot rolled railroad wheel at the steel wheel plant of U.S. Steel's Gary Steel Works, Gary, Indiana. (Russell C. Aikins, photographer)

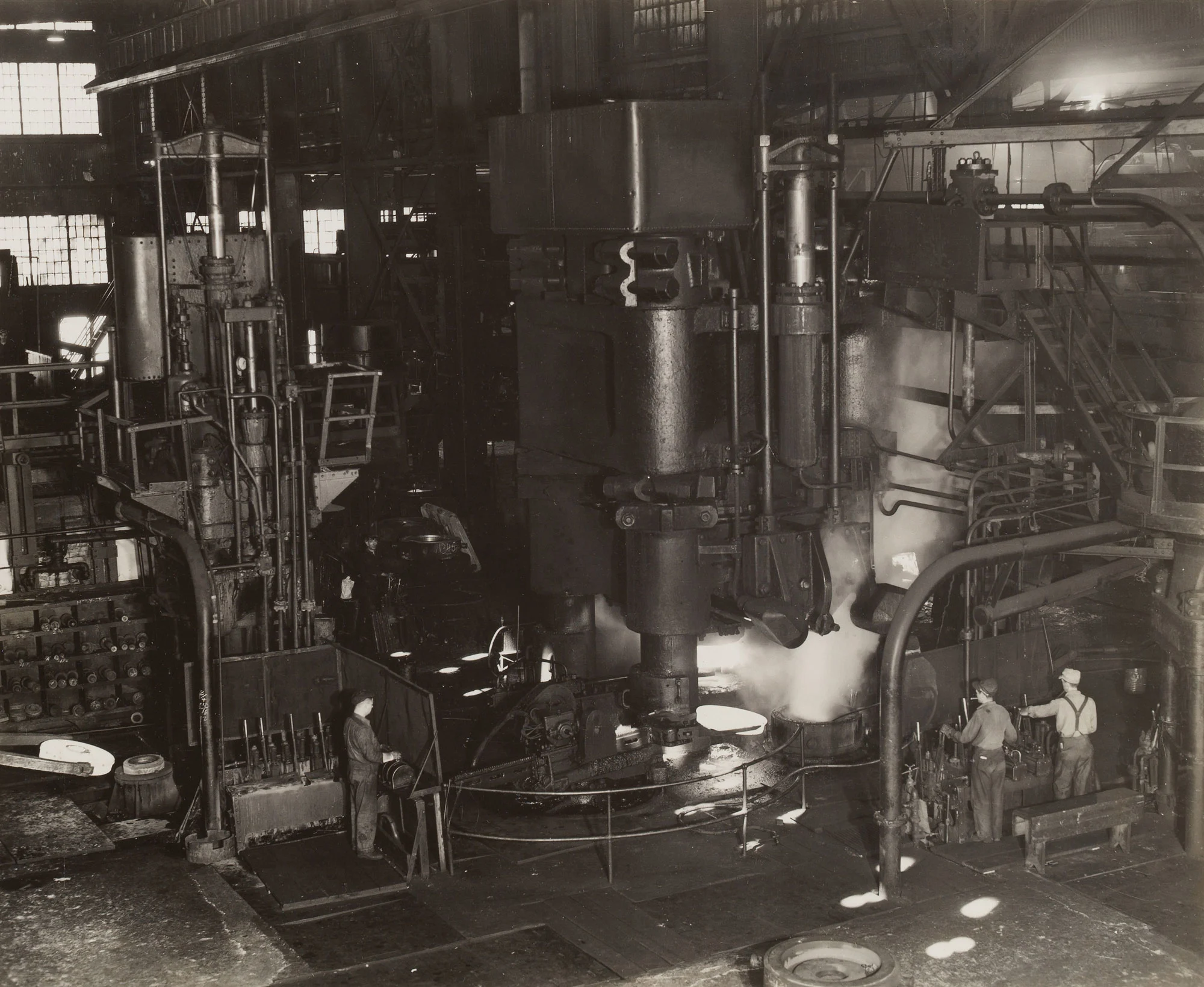

Ten-thousand ton hydraulic press at the wheel mill at U.S. Steel's Gary Steel Works, Gary, Indiana.

Machining wheels preparatory to shipment to railroad companies throughout the country are shown here at U.S. Steel's Gary Steel Works, Gary, Indiana. Finished wheels are shipped in the gondola cars which can be seen in the background.

George Mangos, a machine operator at the Gary Works of U.S. Steel, Gary, Indiana, is shown turning the "tread" of a railroad car wheel. The first two rows of wheels in the foreground have already been turned and the last two are waiting to be done. (Fritz Henle, photographer)

Unfinished railroad car wheels can be seen in the foreground of this photograph taken at U.S. Steel's Gary Steel Works, Gary, Indiana. Finished wheels, ready for shipment, can be seen in the background.

Railroad car wheels for America's rolling stock are shown ready for shipment from the wheel mill department at U.S. Steel's Gary Steel Works, Gary, Indiana.

Wheels by the hundreds ready for shipment from U.S. Steel's Gary Steel Works, Gary, Indiana, to railroad and car-building companies throughout the United States.

Teamwork is stressed here as this crew are shown in the process of forging a railroad car axle at U.S. Steel's Gary Steel Works, Gary, Indiana.

Inspection of axles at U.S. Steel's Gary Steel Works, Gary, Indiana. Axles are formed by a combination of rolling and forging. The axle bloom is rolled to wheel seat size and the forming is completed by hammer forging. After straightening, a lathe finishes the axle according to specifications.

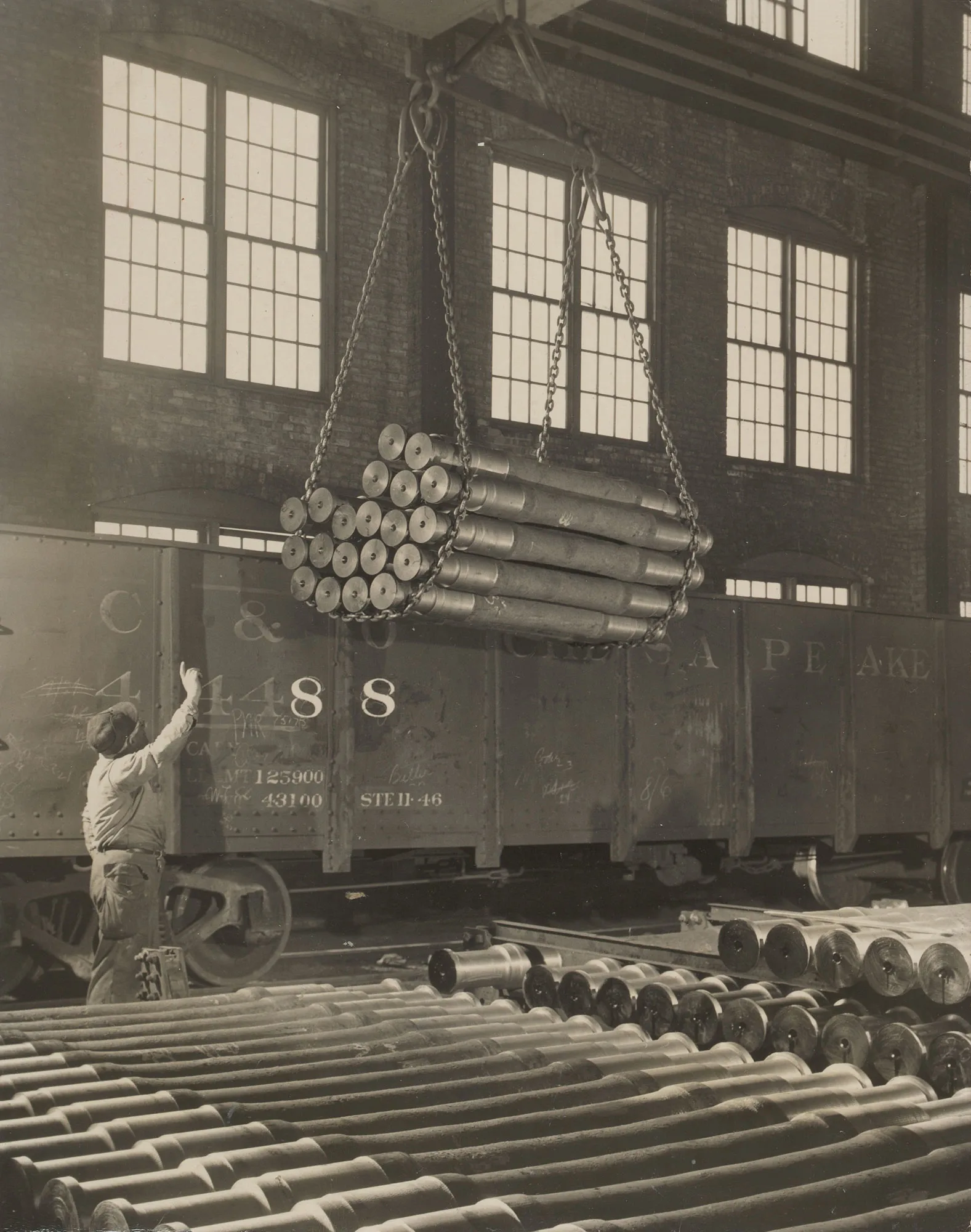

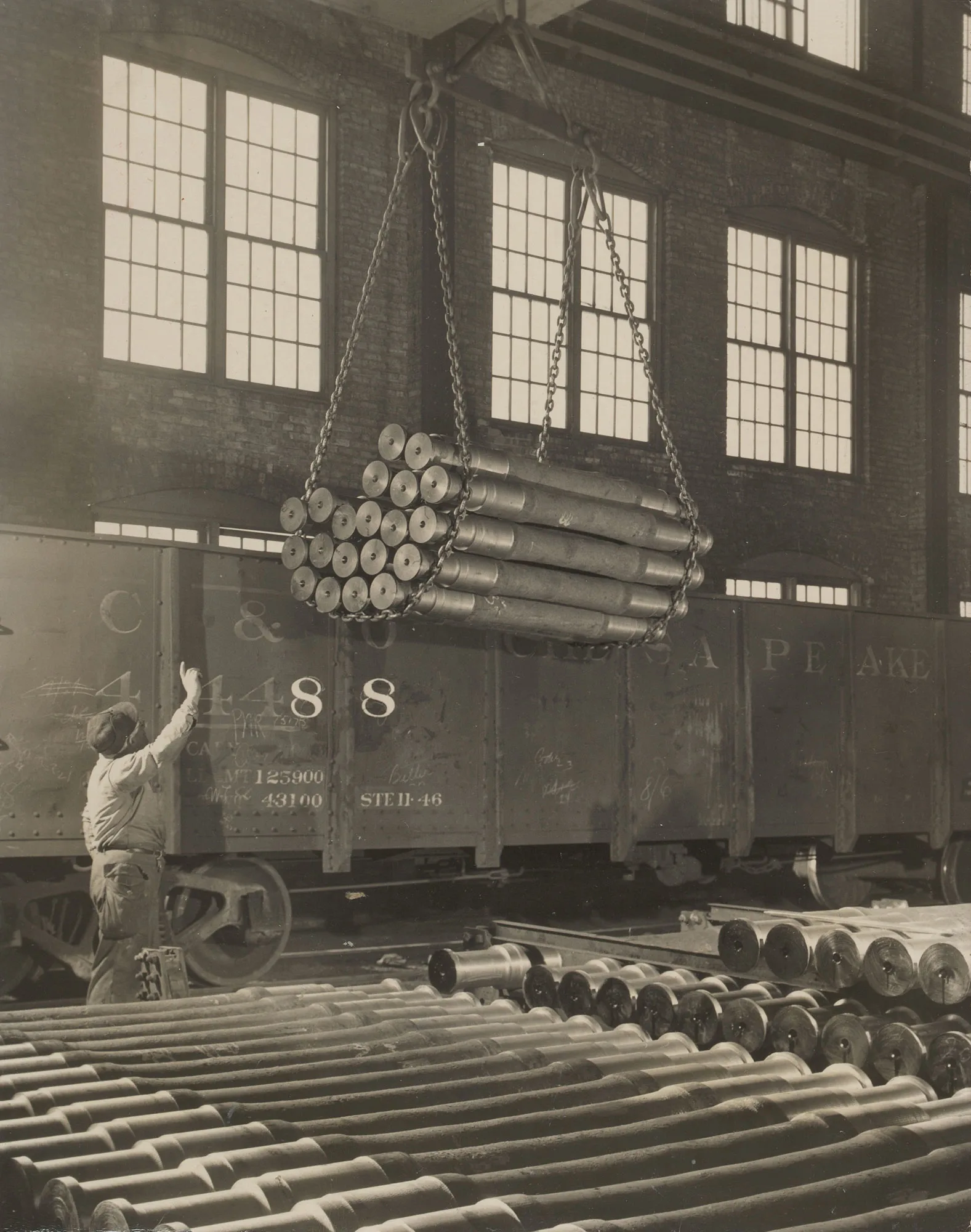

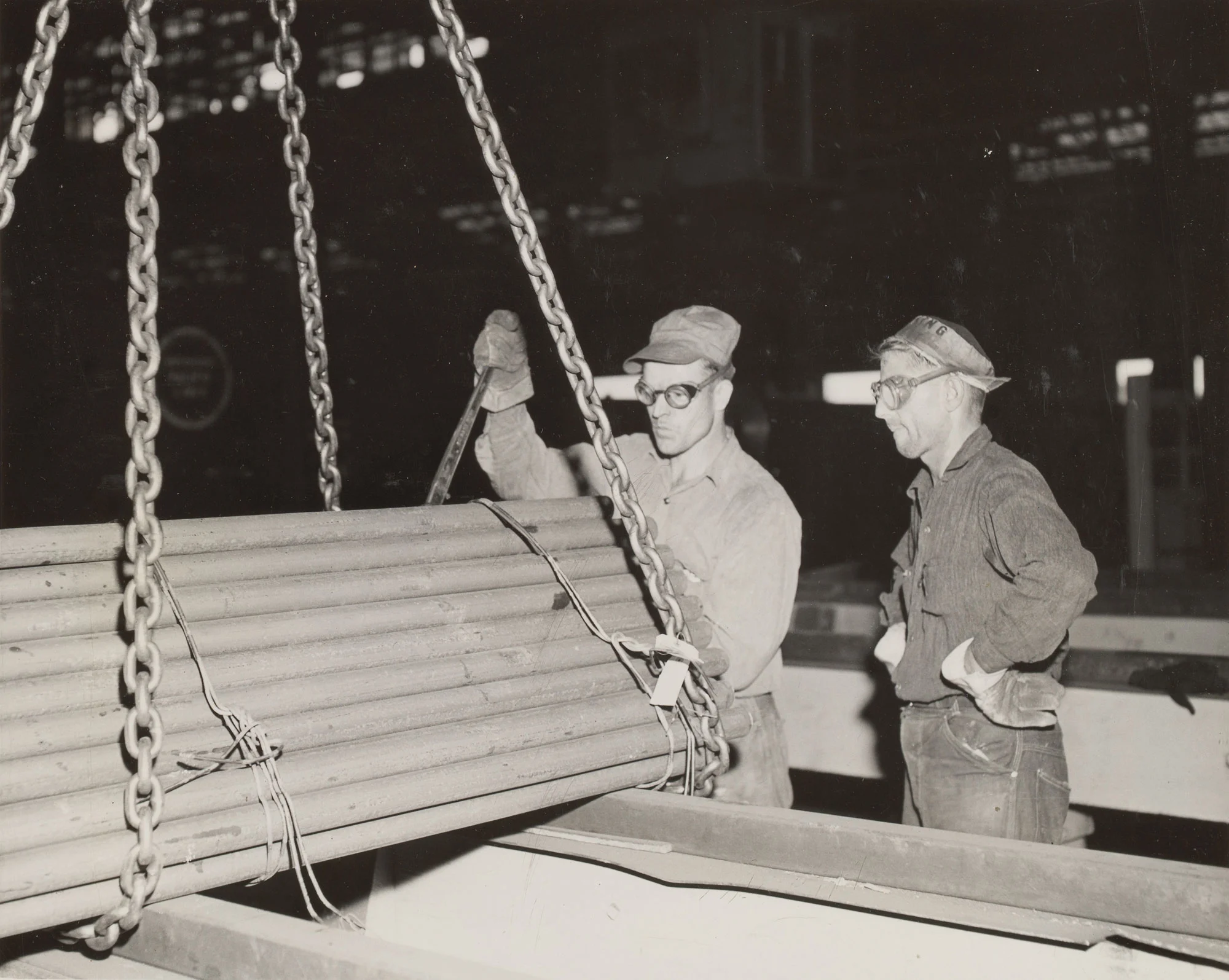

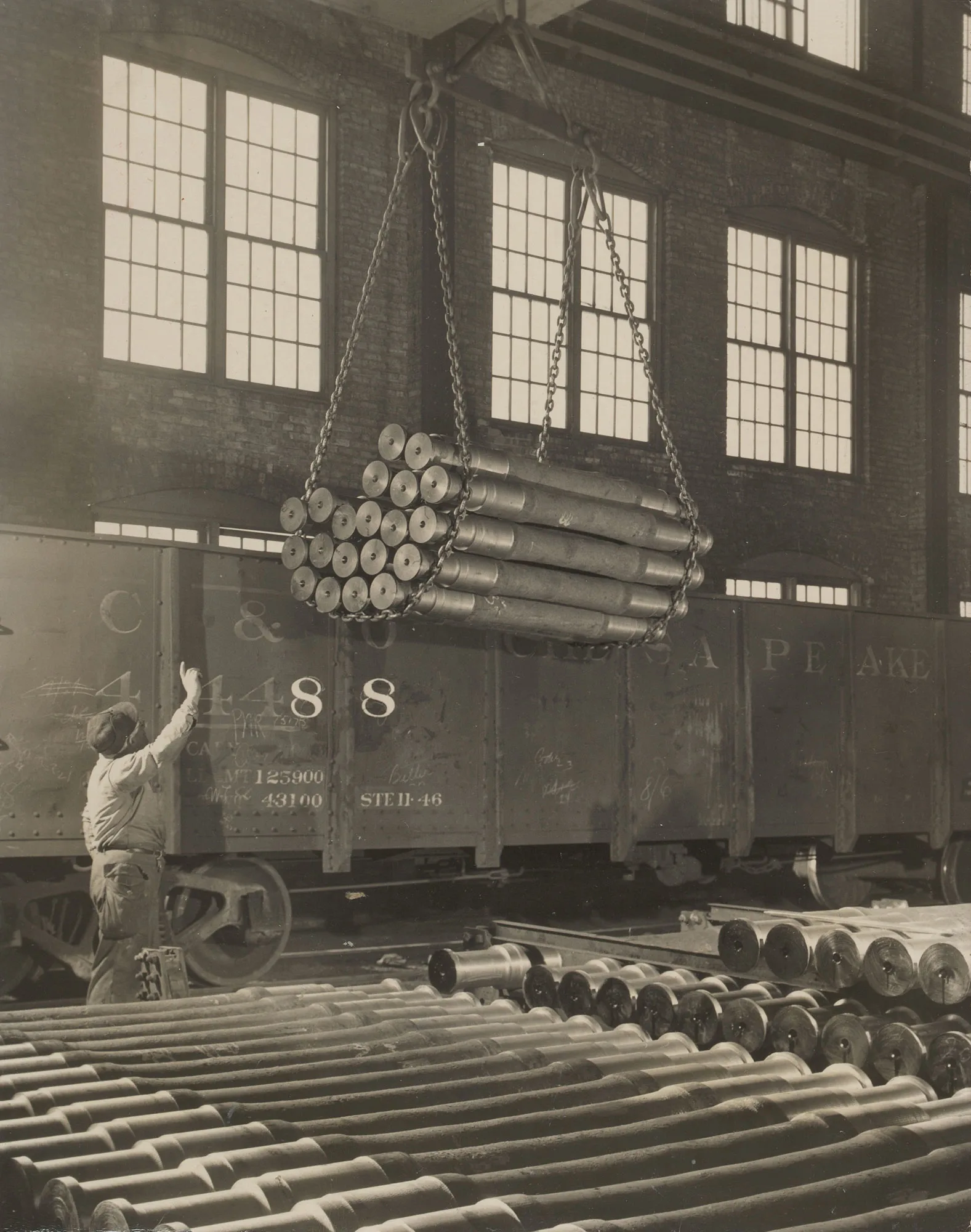

Axles to help relieve the freight car shortage are loaded for shipment at U.S. Steel's Gary Steel Works, Gary, Indiana. Each of these 1020 pound axles will help American railroads roll their record peacetime consignments. The axles are forged from special steel and then machined. On the lower left giving a signal to the crane operator above is Bennis S. Blajsczak, assistant shipper, of 1736 Pennsylvania Street, Gary.

Over 3,000 rolls, ranging in size from 9 inches to 42 inches in diameter and weighing up to 25 tons each are shown in the roll storage yard at the U.S. Steel's Gary Steel Works, Gary, Indiana. There are over 10,000 rolls of various sizes and shapes in constant daily use at this plant. John Marietta and Mike Urschel, hookers, are the men in this picture. (Russell C. Aikins, photographer)

The loss of an arm doesn't mean the loss of a welding career to Frank Pishkur at U.S. Steel's Gary Steel Works, Gary, Indiana. Before entering the service, Frank was training as a welder. During the Battle of Germany as a staff sergeant in the famed 1st Infantry Division, Frank was hit in the right arm by an exploding artillery shell. In a field hospital it was found necessary to amputate the arm at the shoulder. Frank returned to Gary Works and with special training is now a skilled welder in the Welding Shop.

Technique of fighting a tar fire is demonstrated by plant protection personnel of U.S. Steel's Gary Steel Works, Gary, Indiana, with 1½ inch "paradise" nozzle.

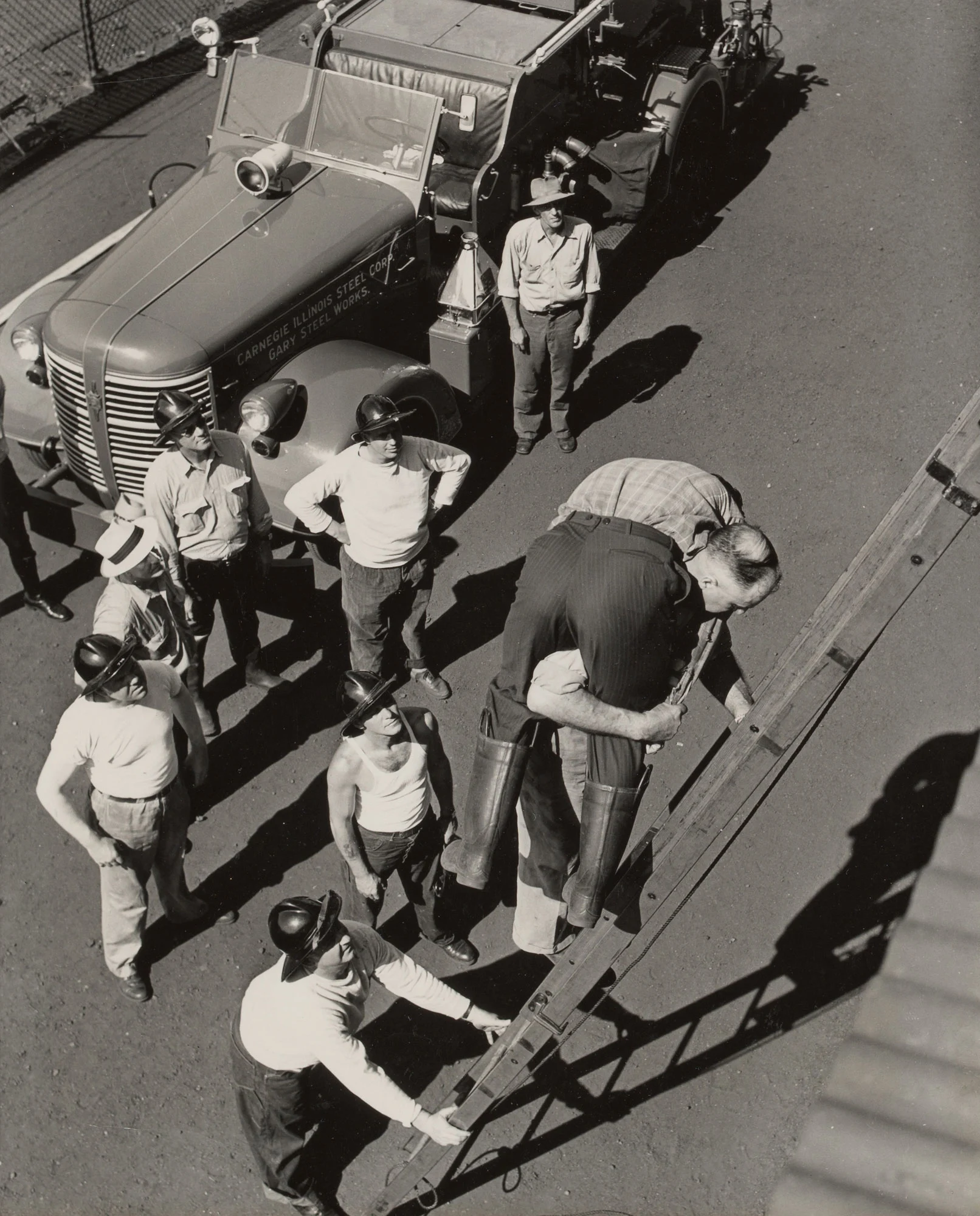

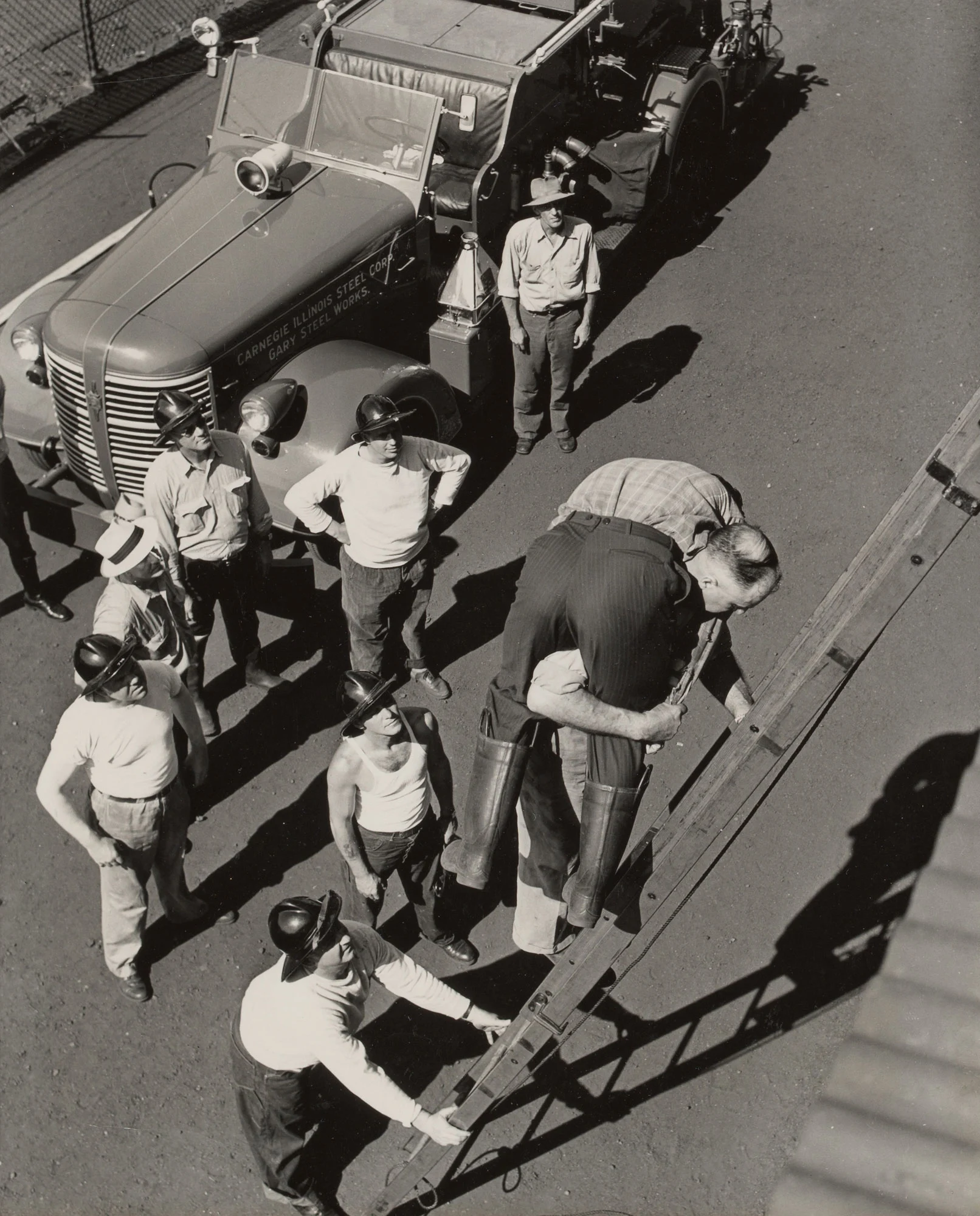

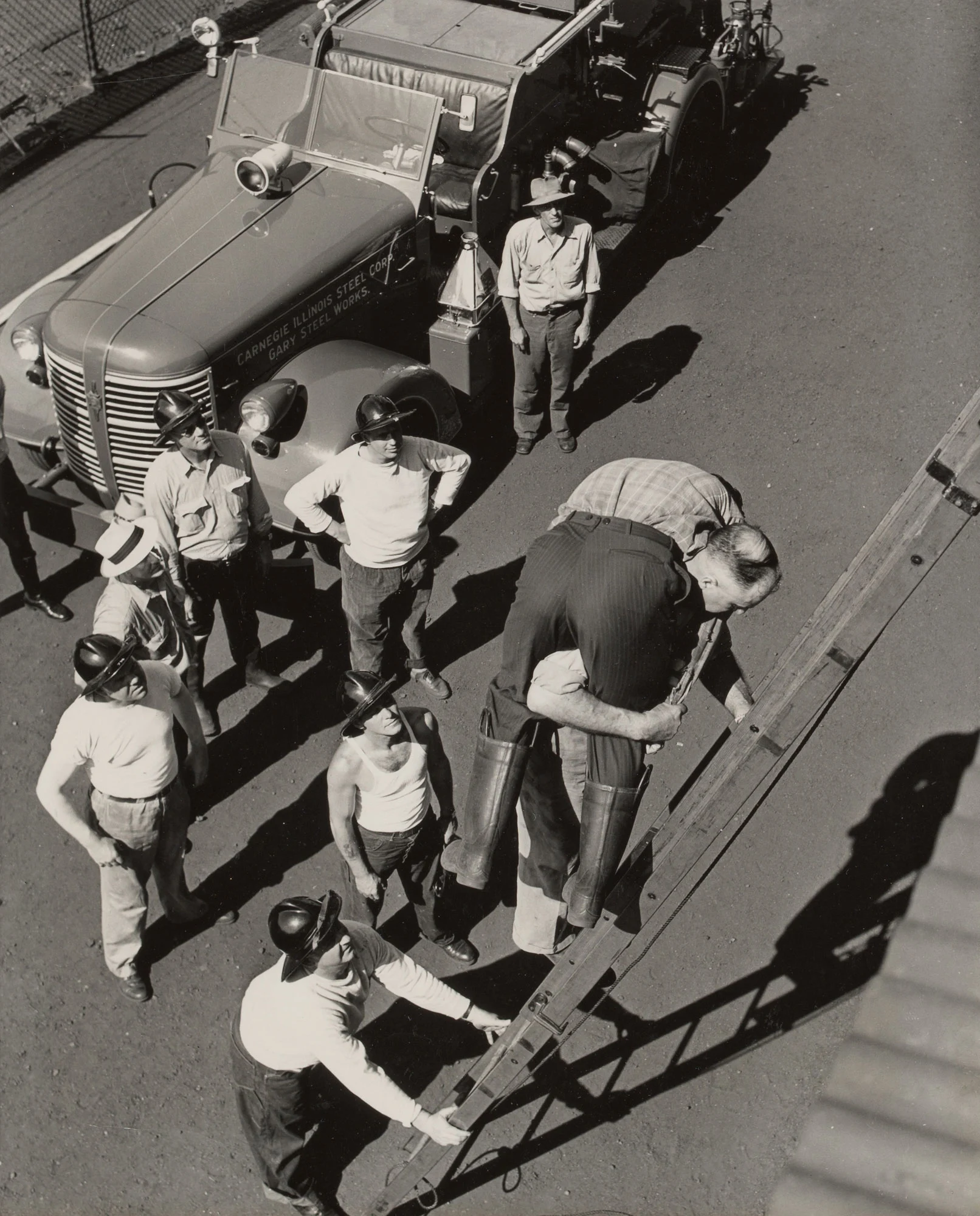

Plant Protection personnel look on as Joe Lump, fire chief in U.S. Steel's Gary Steel Works, Gary, Indiana, demonstrates proper technique in carrying a "victim" down a ladder.

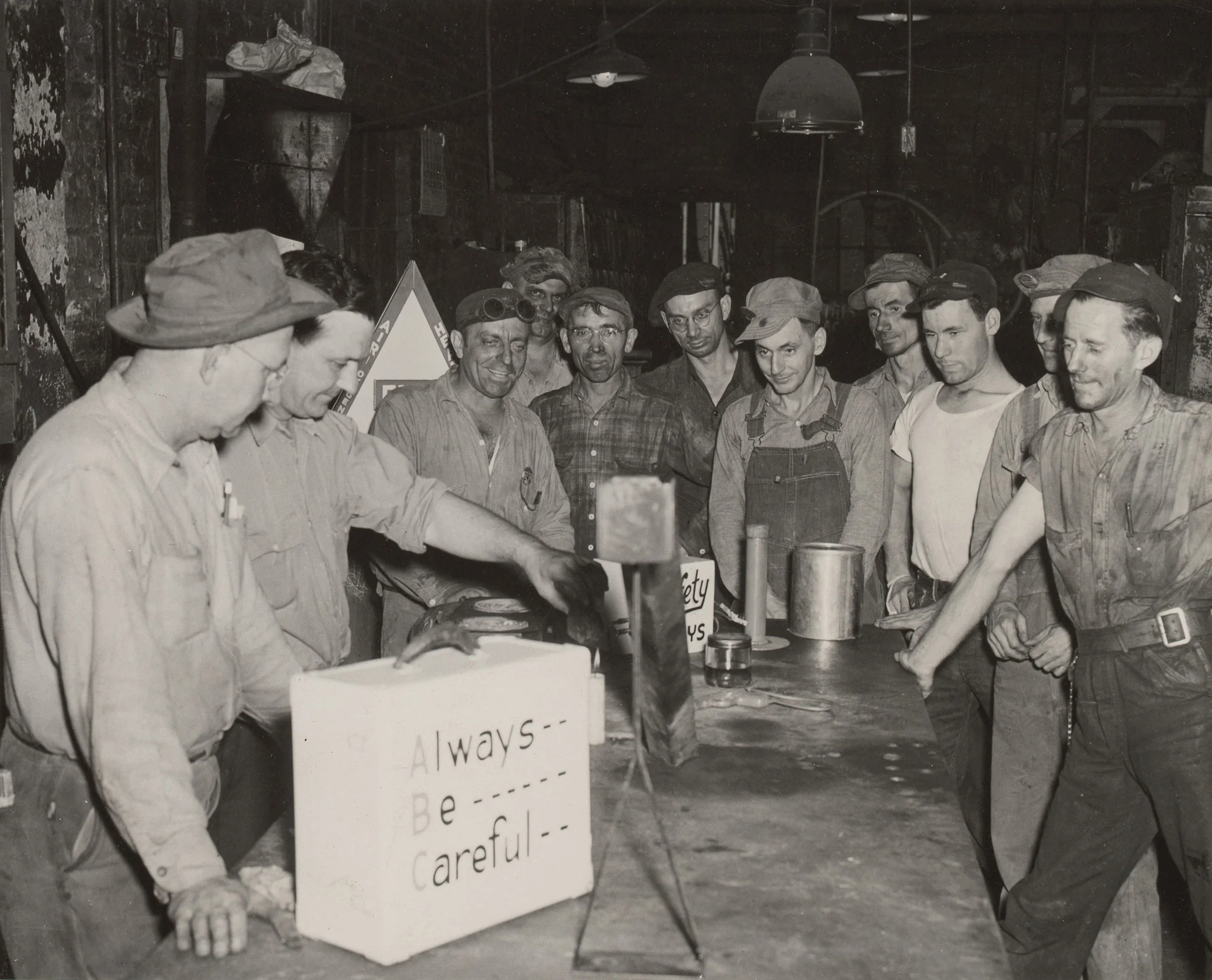

A group of workers at U.S. Steel's Gary Steel Works, Gary, Indiana, are shown the correct method of extinguishing an electric motor fire with a carbon dioxide (CO2) extinguisher.

Ore Bridge Operators in U.S. Steel's Gary Steel Works, Gary, Indiana, are shown how to operate a carbon tetrachloride (C2Cl4) extinguisher.

Inhalator squad at U.S. Steel's Gary Steel Works, Gary, Indiana, practices proper method of resuscitation using the Schaefer Prone Pressure method combined with an auxiliary inhalator.

Inhalator squad at U.S. Steel's Gary Steel Works, Gary, Indiana, practices proper method of resuscitation using the Schaefer Prone Pressure method combined with an auxiliary inhalator.

Fred Bowers, assistant fire chief at U.S. Steel's Gary Steel Works, Gary Indiana, demonstrates to open hearth workers the downward course of gasoline fumes.

A new employee receives safety instruction at U.S. Steel's Gary Steel Works, Gary, Indiana. Although grinder has a safety guard, goggles are an added precaution.

BIRD'S EYE VIEW of a portion of the world's largest steel mill, the Gary, Indiana, Works of United States Steel. In the background on the right can be seen six of the plants twelve blast furnaces and on the left two of the open hearth shops. (Fritz Henle, photographer)

Charging machine with view of the "peel" as contents of box is dumped into No. 88 furnace at U.S. Steel's Gary Steel Works, Gary, Indiana. The cluster of 3500-watt lamps near the top of A-frame, supporting power collector bars, gives excellent lighting conditions. On the charging floor can be seen a neat pile of ground basic slag, besides a larger pile of burned dolomite in the near foreground, a pile of granite dolomite. (Fred Korth, photographer)

Molten iron from one of the 12 blast furnaces at U.S. Steel's Gary, Indiana, Works runs into a ladle car, in foreground, for transfer to an open hearth stop. (Fritz Henle, photographer)

Tubing is welded electrically at the No. 5 weld mill of U.S. Steel's National Tube Company plant in Gary, Indiana. (Fritz Henle, photographer)

A view of the charging floor in the open hearth building at U.S. Steel's Gary Steel Works, Gary, Indiana. One of the furnaces is receiving a charge of molten iron from the blast furnace.

Open hearth crew "making bottom" with dolomite in an open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana.

Charging machine with view of the "peel" as contents of box is dumped into No. 88 furnace at U.S. Steel's Gary Steel Works, Gary, Indiana. The cluster of 3500-watt lamps near the top of A-frame, supporting power collector bars, gives excellent lighting conditions. On the charging floor can be seen a neat pile of ground basic slag, besides a larger pile of burned dolomite in the near foreground, a pile of granite dolomite. (Fred Korth, photographer)

One hundred tons of molten iron is shown being poured into an open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana.

Pouring 100 tons of blast furnace iron into an open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana. (Fred Korth, photographer)

An employee is seen gazing into the "electric eye" temperature control device in following the progress of the heat in this furnace at U.S. Steel's Gary Steel Works, Gary, Indiana.

An employee in U.S. Steel's Gary Steel Works, Gary, Indiana, inspects the control dial of an "electric eye" to observe the temperature indications of a heat of steel in this open hearth furnace. (Shay's Photography)

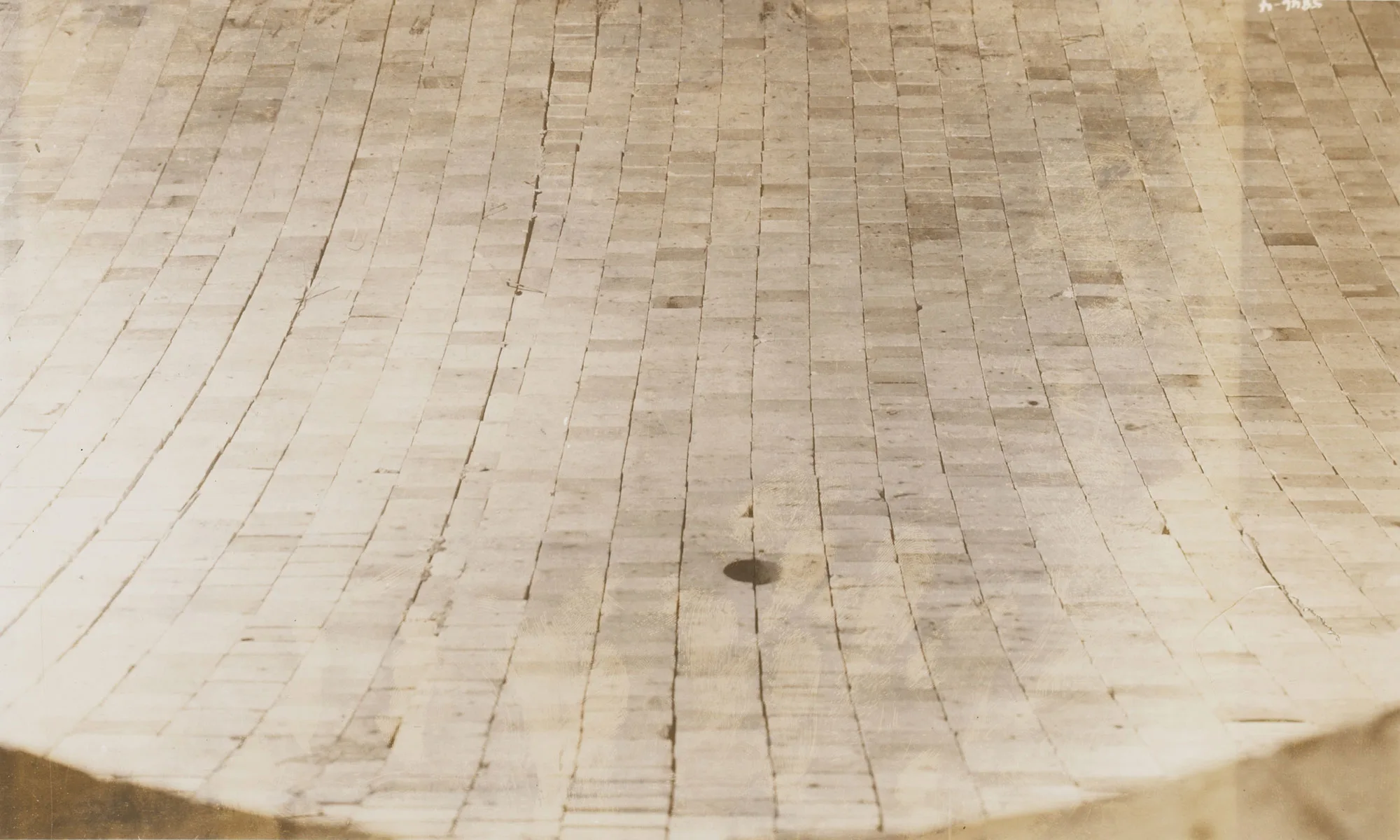

The inside of the "electric eye" is shown in this view as it appears in an inactive open hearth furnace at S. Steel's Gary Steel Works, Gary, Indiana. (Shay's Photography)

How the inside end of the "electric eye" temperature control appears in active open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana, is shown is this view taken through the door of an active furnace. The terrific heat of the molten mass is indicated by the line of flame running horizontally across the picture just above the "eye" end. (Shay's Photography)

TAPPING TEAMWORK. Open hearth workers tap one of the furnaces at U.S. Steel's Gary Steel Works, Gary, Indiana in this scene from U.S. Steel's motion picture, "Unfinished Business." The long rod which they are poking through the hearth of the furnace opens the tap hole on the far side.

First helper burning out the "plug" preparatory to tapping this open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana. (Fred Korth, photographer)

Tapping an open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana. Heavier than slag, the molten steel flows from the furnace first, nearly filling the ladle. Slag follows next and is allowed to overflow into the slag thimble alongside.

INDUSTRIAL FIREWORKS. One of the highlights of U.S. Steel's new motion picture, "Unfinished Business," is this open hearth tapping scene at U.S. Steel's Gary Steel Works, Gary, Indiana.

100-tons of blast furnace iron being poured at the open hearths into transfer ladle at U.S. Steel's Gary Steel Works, Gary, Indiana. (Fred Korth, photographer)

TEAM OF TEEMERS. One of the dramatic highlights in U.S. Steel’s motion picture. "Unfinished Business," is this ingot teeming operation. In this operation at the number 4 open hearth shop of U.S. Steel’s Gary Steel Works, Gary, Indiana, the red hot Molten steel is teemed from the ladle into ingot molds.

A close-up of the steel pourer watching the stream of steel filling an ingot mold at U.S. Steel's Gary Steel Works, Gary Indiana. The stopper rod operating lever which he will use to cut off the stream is resting on the pouring platform at his feet. The crane operator who will move the ladle over each of the moulds can be seen in the crane operating cage just behind the steel ladle. (Fred Korth, photographer)

Ingot molds in transit at U.S. Steel's Gary Steel Works, Gary Indiana. (Robert Yarnall Richie, photographer)

Ingot of steel being lifted from soaking pits after it has been heated to the temperature necessary for subsequently rolling into rails at U.S. Steel's Gary Steel Works, Gary Indiana. (Fred Korth, photographer)

After reheating to uniform temperature throughout, ingots are withdrawn from the soaking pit in the 45-inch slabbing mill at U.S. Steel's Homestead District Works, Munhall, Pennsylvania. John Sitak, of 3320 Lincoln Avenue, West Mifflin, Pennsylvania, looks on. (Fritz Henle, photographer)

An ingot weighing approximately 12 tons is shown entering the rolls of the 44-inch blooming mill at U.S. Steel's Gary Steel Works, Gary, Indiana.

ANIMATION SEQUENCE background in U.S. Steel's new motion picture, "Unfinished Business," was this 44-inch blooming mill at U.S. Steel's Gary Steel Works, Gary, Indiana. This view shows the first of four successive stages in the rolling of an ingot down to a slab.

ANIMATION SEQUENCE background in U.S. Steel's new motion picture, "Unfinished Business," was this 44-inch blooming mill at U.S. Steel's Gary Steel Works, Gary, Indiana. This view shows the second of four successive stages in the rolling of an ingot down to a slab.

ANIMATION SEQUENCE background in U.S. Steel's new motion picture, "Unfinished Business," was this 44-inch blooming mill at U.S. Steel's Gary Steel Works, Gary, Indiana. This view shows the third of four successive stages in the rolling of an ingot down to a slab.

Steam caused by high pressure descaling water striking the hot plate enshrouds the mill at U.S. Steel's Gary Steel Works, Gary, Indiana. (Russell C. Aikins, photographer)

Shifting a red hot steel plate for another pass in the 160-inch plate mill of U.S. Steel's Gary Steel Works, Gary, Indiana. The second hooker seen with the rods are, left to right, Chester P. Kalita, 1651 west 39th Street, Gary, and Victor M. Malis, 1929 Cleveland Street, Gary. This is one of the largest mills in the country engaged in making steel plates for industrial purposes. They are used in structural work by railroads as well as in the building of dams and ships and similar projects.

After cold rolling and shearing to size, sheets are conveyed to the heat treating furnaces where they are heat treated at 1300 degrees Fahrenheit for a specified time, usually about 50 hours. This treatment releases the strains set up in the steel during cold working and imparts ductility and softness. Sheets are placed in piles, covered with annealing boxes and charged into furnaces like this one at U.S. Steel's Gary Steel Works, Gary, Indiana. Temperature is governed by Prometric control. (Shay's Photography)

A five-ton ingot comes out of the second stand of rolls in the 40-inch billet mill at U.S. Steel's Gary Steel Works, Gary, Indiana. The white hot ingot becomes longer and the cross section smaller as it passes through successive stands of rolls, which exert a heavy squeezing pressure. At the left a mill oiler is seen lubricating the table rolls in the line shaft hears. He is Harry C. Countzmar of 2504 Madison Street, Gary.

Billet mill operations, where the intermediate step is taken between the furnaces and the finishing process in the merchant mill at U.S. Steel's Gary Steel Works, Gary, Indiana.

White hot steel comes out of the second stand in the 32-inch billet mill of U.S. Steel's Gary Steel Works, Gary, Indiana. Starting as a five ton ingot, the steel passed through stands of the 40-inch mill and then into the rolls of the 23-inch mill. Each successive stand of rolls squeezes the steel to greater length and smaller cross section. The Gary Works, which is the largest steel mill in the world, employs about 20,000 persons and is located on a 1440 acre site.

A white hot billet comes out of the 24-inch continuous mill in U.S. Steel’s Gary Steel Works, Gary, Indiana. The Billet is reduced to this size after starting in the rolls as a five ton ingot. It is seen here after having passed through first the 40-inch billet mill rolls, then those of the 32-inch mill and then the 24-inch mill. This is but one phase of operation in the largest steel mill in the world, the Gary Works, which is built on a 1440 acre site and employs about 20,000 persons.

An interior view of the rail mill at U.S. Steel's Gary Steel Works, Gary, Indiana. Various intermediate stages involved in the rolling of an ingot into rails is shown in this photograph.

Sparks fly ceiling-ward as the hot saws cut the rails into 39-foot sections at U.S. Steel's Gary Steel Works, Gary, Indiana.

Sparks fly ceiling-ward as the hot saws cut the rails into 39-foot sections at U.S. Steel's Gary Steel Works, Gary, Indiana.

Gauging the bolt holes in the new rails at the rail mill of U.S. Steel's Gary Steel Works, Gary, Indiana. The check is being made by Herbert E. Tilden, final Inspector of rails, of 2560 Monnier Road, Gary. In his left hand, partly hidden from view, is a gauge which determines if each hole is the proper distance from the base of the rail. In his right hand, he holds a gauge which shows whether or not the holes are the right distance apart and from the end of the rail.

Nick and break test for rails shown being made in the rail mill at U.S. Steel's Gary Steel Works, Gary, Indiana. A nick is cut in a section of rail. It is placed under the hydraulic hammer seen here and a gag maul held with an edge in the nick. The hammer exerts 1200 pounds of pressure on the flat top of the maul, which breaks the rail. Inspection of the segments determines if the steel is sound. Holding the maul handle is Michael E. Roll, mill inspector of 4782 Cleveland Street, Gary.

General view of a section of the wheel mill of U.S. Steel's Gary Steel Works, Gary, Indiana, where wrought steel wheels are made. Blocks to form a wheel of the desired weight and dimensions are cut from round blooms, preheated, and then forged into a wheel blank in a press. The bore is punched out and the blank after being reheated, is sent to the wheel rolling mill for further shaping. The wheel is later machined to meet specifications.

A red hot wheel block is taken from a reheating furnace preparatory to being forged into a freight car wheel in the wheel mill of U.S. Steel's Gary Steel Works, Gary, Indiana. The block weighs 930 pounds. Signaling the operator of the "claw" crane is Peter Chacharis, general maintenance foreman of the wheel mill, 316 Monroe Street, Gary. This is but one phase of operations in the Gary Works, which is the largest steel mill in the world.

Removing a red hot freight car wheel from a die where it just has been shaped by 10,000 tons of hydraulic pressure in the wheel mill at U.S. Steel's Gary Steel Works, Gary, Indiana. The wheel is 28 inches in diameter. Seen at the right blowing the scale out of the lower die with compressed air is Rudolph C. Krieger, pressman, of 725 Virginia Street, Gary. The Gary Works is the largest steel mill in the world. It employs about 20,000 persons and is located on a 1440 acre site.

Louis K. Soteros, conning press operator, shaping hub and plate of hot rolled railroad wheel at the steel wheel plant of U.S. Steel's Gary Steel Works, Gary, Indiana. (Russell C. Aikins, photographer)

Ten-thousand ton hydraulic press at the wheel mill at U.S. Steel's Gary Steel Works, Gary, Indiana.

Machining wheels preparatory to shipment to railroad companies throughout the country are shown here at U.S. Steel's Gary Steel Works, Gary, Indiana. Finished wheels are shipped in the gondola cars which can be seen in the background.

George Mangos, a machine operator at the Gary Works of U.S. Steel, Gary, Indiana, is shown turning the "tread" of a railroad car wheel. The first two rows of wheels in the foreground have already been turned and the last two are waiting to be done. (Fritz Henle, photographer)

Unfinished railroad car wheels can be seen in the foreground of this photograph taken at U.S. Steel's Gary Steel Works, Gary, Indiana. Finished wheels, ready for shipment, can be seen in the background.

Railroad car wheels for America's rolling stock are shown ready for shipment from the wheel mill department at U.S. Steel's Gary Steel Works, Gary, Indiana.

Wheels by the hundreds ready for shipment from U.S. Steel's Gary Steel Works, Gary, Indiana, to railroad and car-building companies throughout the United States.

Teamwork is stressed here as this crew are shown in the process of forging a railroad car axle at U.S. Steel's Gary Steel Works, Gary, Indiana.

Inspection of axles at U.S. Steel's Gary Steel Works, Gary, Indiana. Axles are formed by a combination of rolling and forging. The axle bloom is rolled to wheel seat size and the forming is completed by hammer forging. After straightening, a lathe finishes the axle according to specifications.

Axles to help relieve the freight car shortage are loaded for shipment at U.S. Steel's Gary Steel Works, Gary, Indiana. Each of these 1020 pound axles will help American railroads roll their record peacetime consignments. The axles are forged from special steel and then machined. On the lower left giving a signal to the crane operator above is Bennis S. Blajsczak, assistant shipper, of 1736 Pennsylvania Street, Gary.

Over 3,000 rolls, ranging in size from 9 inches to 42 inches in diameter and weighing up to 25 tons each are shown in the roll storage yard at the U.S. Steel's Gary Steel Works, Gary, Indiana. There are over 10,000 rolls of various sizes and shapes in constant daily use at this plant. John Marietta and Mike Urschel, hookers, are the men in this picture. (Russell C. Aikins, photographer)

The loss of an arm doesn't mean the loss of a welding career to Frank Pishkur at U.S. Steel's Gary Steel Works, Gary, Indiana. Before entering the service, Frank was training as a welder. During the Battle of Germany as a staff sergeant in the famed 1st Infantry Division, Frank was hit in the right arm by an exploding artillery shell. In a field hospital it was found necessary to amputate the arm at the shoulder. Frank returned to Gary Works and with special training is now a skilled welder in the Welding Shop.

Technique of fighting a tar fire is demonstrated by plant protection personnel of U.S. Steel's Gary Steel Works, Gary, Indiana, with 1½ inch "paradise" nozzle.

Plant Protection personnel look on as Joe Lump, fire chief in U.S. Steel's Gary Steel Works, Gary, Indiana, demonstrates proper technique in carrying a "victim" down a ladder.

A group of workers at U.S. Steel's Gary Steel Works, Gary, Indiana, are shown the correct method of extinguishing an electric motor fire with a carbon dioxide (CO2) extinguisher.

Ore Bridge Operators in U.S. Steel's Gary Steel Works, Gary, Indiana, are shown how to operate a carbon tetrachloride (C2Cl4) extinguisher.

Inhalator squad at U.S. Steel's Gary Steel Works, Gary, Indiana, practices proper method of resuscitation using the Schaefer Prone Pressure method combined with an auxiliary inhalator.

Inhalator squad at U.S. Steel's Gary Steel Works, Gary, Indiana, practices proper method of resuscitation using the Schaefer Prone Pressure method combined with an auxiliary inhalator.

Fred Bowers, assistant fire chief at U.S. Steel's Gary Steel Works, Gary Indiana, demonstrates to open hearth workers the downward course of gasoline fumes.

A new employee receives safety instruction at U.S. Steel's Gary Steel Works, Gary, Indiana. Although grinder has a safety guard, goggles are an added precaution.

Safety instruction to the new employee at U.S. Steel's Gary Steel Works, Gary, Indiana, regarding the safe way to cut wire on bundles of steel.

Charging machine with view of the "peel" as contents of box is dumped into No. 88 furnace at U.S. Steel's Gary Steel Works, Gary, Indiana. The cluster of 3500-watt lamps near the top of A-frame, supporting power collector bars, gives excellent lighting conditions. On the charging floor can be seen a neat pile of ground basic slag, besides a larger pile of burned dolomite in the near foreground, a pile of granite dolomite. (Fred Korth, photographer)

Molten iron from one of the 12 blast furnaces at U.S. Steel's Gary, Indiana, Works runs into a ladle car, in foreground, for transfer to an open hearth stop. (Fritz Henle, photographer)

Tubing is welded electrically at the No. 5 weld mill of U.S. Steel's National Tube Company plant in Gary, Indiana. (Fritz Henle, photographer)

A view of the charging floor in the open hearth building at U.S. Steel's Gary Steel Works, Gary, Indiana. One of the furnaces is receiving a charge of molten iron from the blast furnace.

Open hearth crew "making bottom" with dolomite in an open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana.

Charging machine with view of the "peel" as contents of box is dumped into No. 88 furnace at U.S. Steel's Gary Steel Works, Gary, Indiana. The cluster of 3500-watt lamps near the top of A-frame, supporting power collector bars, gives excellent lighting conditions. On the charging floor can be seen a neat pile of ground basic slag, besides a larger pile of burned dolomite in the near foreground, a pile of granite dolomite. (Fred Korth, photographer)

One hundred tons of molten iron is shown being poured into an open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana.

Pouring 100 tons of blast furnace iron into an open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana. (Fred Korth, photographer)

An employee is seen gazing into the "electric eye" temperature control device in following the progress of the heat in this furnace at U.S. Steel's Gary Steel Works, Gary, Indiana.

An employee in U.S. Steel's Gary Steel Works, Gary, Indiana, inspects the control dial of an "electric eye" to observe the temperature indications of a heat of steel in this open hearth furnace. (Shay's Photography)

The inside of the "electric eye" is shown in this view as it appears in an inactive open hearth furnace at S. Steel's Gary Steel Works, Gary, Indiana. (Shay's Photography)

How the inside end of the "electric eye" temperature control appears in active open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana, is shown is this view taken through the door of an active furnace. The terrific heat of the molten mass is indicated by the line of flame running horizontally across the picture just above the "eye" end. (Shay's Photography)

TAPPING TEAMWORK. Open hearth workers tap one of the furnaces at U.S. Steel's Gary Steel Works, Gary, Indiana in this scene from U.S. Steel's motion picture, "Unfinished Business." The long rod which they are poking through the hearth of the furnace opens the tap hole on the far side.

First helper burning out the "plug" preparatory to tapping this open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana. (Fred Korth, photographer)

Tapping an open hearth furnace at U.S. Steel's Gary Steel Works, Gary, Indiana. Heavier than slag, the molten steel flows from the furnace first, nearly filling the ladle. Slag follows next and is allowed to overflow into the slag thimble alongside.

INDUSTRIAL FIREWORKS. One of the highlights of U.S. Steel's new motion picture, "Unfinished Business," is this open hearth tapping scene at U.S. Steel's Gary Steel Works, Gary, Indiana.

100-tons of blast furnace iron being poured at the open hearths into transfer ladle at U.S. Steel's Gary Steel Works, Gary, Indiana. (Fred Korth, photographer)

TEAM OF TEEMERS. One of the dramatic highlights in U.S. Steel’s motion picture. "Unfinished Business," is this ingot teeming operation. In this operation at the number 4 open hearth shop of U.S. Steel’s Gary Steel Works, Gary, Indiana, the red hot Molten steel is teemed from the ladle into ingot molds.

A close-up of the steel pourer watching the stream of steel filling an ingot mold at U.S. Steel's Gary Steel Works, Gary Indiana. The stopper rod operating lever which he will use to cut off the stream is resting on the pouring platform at his feet. The crane operator who will move the ladle over each of the moulds can be seen in the crane operating cage just behind the steel ladle. (Fred Korth, photographer)

Ingot molds in transit at U.S. Steel's Gary Steel Works, Gary Indiana. (Robert Yarnall Richie, photographer)

Ingot of steel being lifted from soaking pits after it has been heated to the temperature necessary for subsequently rolling into rails at U.S. Steel's Gary Steel Works, Gary Indiana. (Fred Korth, photographer)

After reheating to uniform temperature throughout, ingots are withdrawn from the soaking pit in the 45-inch slabbing mill at U.S. Steel's Homestead District Works, Munhall, Pennsylvania. John Sitak, of 3320 Lincoln Avenue, West Mifflin, Pennsylvania, looks on. (Fritz Henle, photographer)

An ingot weighing approximately 12 tons is shown entering the rolls of the 44-inch blooming mill at U.S. Steel's Gary Steel Works, Gary, Indiana.

ANIMATION SEQUENCE background in U.S. Steel's new motion picture, "Unfinished Business," was this 44-inch blooming mill at U.S. Steel's Gary Steel Works, Gary, Indiana. This view shows the first of four successive stages in the rolling of an ingot down to a slab.

ANIMATION SEQUENCE background in U.S. Steel's new motion picture, "Unfinished Business," was this 44-inch blooming mill at U.S. Steel's Gary Steel Works, Gary, Indiana. This view shows the second of four successive stages in the rolling of an ingot down to a slab.

ANIMATION SEQUENCE background in U.S. Steel's new motion picture, "Unfinished Business," was this 44-inch blooming mill at U.S. Steel's Gary Steel Works, Gary, Indiana. This view shows the third of four successive stages in the rolling of an ingot down to a slab.

Steam caused by high pressure descaling water striking the hot plate enshrouds the mill at U.S. Steel's Gary Steel Works, Gary, Indiana. (Russell C. Aikins, photographer)

Shifting a red hot steel plate for another pass in the 160-inch plate mill of U.S. Steel's Gary Steel Works, Gary, Indiana. The second hooker seen with the rods are, left to right, Chester P. Kalita, 1651 west 39th Street, Gary, and Victor M. Malis, 1929 Cleveland Street, Gary. This is one of the largest mills in the country engaged in making steel plates for industrial purposes. They are used in structural work by railroads as well as in the building of dams and ships and similar projects.

After cold rolling and shearing to size, sheets are conveyed to the heat treating furnaces where they are heat treated at 1300 degrees Fahrenheit for a specified time, usually about 50 hours. This treatment releases the strains set up in the steel during cold working and imparts ductility and softness. Sheets are placed in piles, covered with annealing boxes and charged into furnaces like this one at U.S. Steel's Gary Steel Works, Gary, Indiana. Temperature is governed by Prometric control. (Shay's Photography)

A five-ton ingot comes out of the second stand of rolls in the 40-inch billet mill at U.S. Steel's Gary Steel Works, Gary, Indiana. The white hot ingot becomes longer and the cross section smaller as it passes through successive stands of rolls, which exert a heavy squeezing pressure. At the left a mill oiler is seen lubricating the table rolls in the line shaft hears. He is Harry C. Countzmar of 2504 Madison Street, Gary.

Billet mill operations, where the intermediate step is taken between the furnaces and the finishing process in the merchant mill at U.S. Steel's Gary Steel Works, Gary, Indiana.

White hot steel comes out of the second stand in the 32-inch billet mill of U.S. Steel's Gary Steel Works, Gary, Indiana. Starting as a five ton ingot, the steel passed through stands of the 40-inch mill and then into the rolls of the 23-inch mill. Each successive stand of rolls squeezes the steel to greater length and smaller cross section. The Gary Works, which is the largest steel mill in the world, employs about 20,000 persons and is located on a 1440 acre site.

A white hot billet comes out of the 24-inch continuous mill in U.S. Steel’s Gary Steel Works, Gary, Indiana. The Billet is reduced to this size after starting in the rolls as a five ton ingot. It is seen here after having passed through first the 40-inch billet mill rolls, then those of the 32-inch mill and then the 24-inch mill. This is but one phase of operation in the largest steel mill in the world, the Gary Works, which is built on a 1440 acre site and employs about 20,000 persons.

An interior view of the rail mill at U.S. Steel's Gary Steel Works, Gary, Indiana. Various intermediate stages involved in the rolling of an ingot into rails is shown in this photograph.

Sparks fly ceiling-ward as the hot saws cut the rails into 39-foot sections at U.S. Steel's Gary Steel Works, Gary, Indiana.

Sparks fly ceiling-ward as the hot saws cut the rails into 39-foot sections at U.S. Steel's Gary Steel Works, Gary, Indiana.

Gauging the bolt holes in the new rails at the rail mill of U.S. Steel's Gary Steel Works, Gary, Indiana. The check is being made by Herbert E. Tilden, final Inspector of rails, of 2560 Monnier Road, Gary. In his left hand, partly hidden from view, is a gauge which determines if each hole is the proper distance from the base of the rail. In his right hand, he holds a gauge which shows whether or not the holes are the right distance apart and from the end of the rail.

Nick and break test for rails shown being made in the rail mill at U.S. Steel's Gary Steel Works, Gary, Indiana. A nick is cut in a section of rail. It is placed under the hydraulic hammer seen here and a gag maul held with an edge in the nick. The hammer exerts 1200 pounds of pressure on the flat top of the maul, which breaks the rail. Inspection of the segments determines if the steel is sound. Holding the maul handle is Michael E. Roll, mill inspector of 4782 Cleveland Street, Gary.

General view of a section of the wheel mill of U.S. Steel's Gary Steel Works, Gary, Indiana, where wrought steel wheels are made. Blocks to form a wheel of the desired weight and dimensions are cut from round blooms, preheated, and then forged into a wheel blank in a press. The bore is punched out and the blank after being reheated, is sent to the wheel rolling mill for further shaping. The wheel is later machined to meet specifications.

A red hot wheel block is taken from a reheating furnace preparatory to being forged into a freight car wheel in the wheel mill of U.S. Steel's Gary Steel Works, Gary, Indiana. The block weighs 930 pounds. Signaling the operator of the "claw" crane is Peter Chacharis, general maintenance foreman of the wheel mill, 316 Monroe Street, Gary. This is but one phase of operations in the Gary Works, which is the largest steel mill in the world.

Removing a red hot freight car wheel from a die where it just has been shaped by 10,000 tons of hydraulic pressure in the wheel mill at U.S. Steel's Gary Steel Works, Gary, Indiana. The wheel is 28 inches in diameter. Seen at the right blowing the scale out of the lower die with compressed air is Rudolph C. Krieger, pressman, of 725 Virginia Street, Gary. The Gary Works is the largest steel mill in the world. It employs about 20,000 persons and is located on a 1440 acre site.

Louis K. Soteros, conning press operator, shaping hub and plate of hot rolled railroad wheel at the steel wheel plant of U.S. Steel's Gary Steel Works, Gary, Indiana. (Russell C. Aikins, photographer)

Ten-thousand ton hydraulic press at the wheel mill at U.S. Steel's Gary Steel Works, Gary, Indiana.

Machining wheels preparatory to shipment to railroad companies throughout the country are shown here at U.S. Steel's Gary Steel Works, Gary, Indiana. Finished wheels are shipped in the gondola cars which can be seen in the background.

George Mangos, a machine operator at the Gary Works of U.S. Steel, Gary, Indiana, is shown turning the "tread" of a railroad car wheel. The first two rows of wheels in the foreground have already been turned and the last two are waiting to be done. (Fritz Henle, photographer)

Unfinished railroad car wheels can be seen in the foreground of this photograph taken at U.S. Steel's Gary Steel Works, Gary, Indiana. Finished wheels, ready for shipment, can be seen in the background.

Railroad car wheels for America's rolling stock are shown ready for shipment from the wheel mill department at U.S. Steel's Gary Steel Works, Gary, Indiana.

Wheels by the hundreds ready for shipment from U.S. Steel's Gary Steel Works, Gary, Indiana, to railroad and car-building companies throughout the United States.

Teamwork is stressed here as this crew are shown in the process of forging a railroad car axle at U.S. Steel's Gary Steel Works, Gary, Indiana.

Inspection of axles at U.S. Steel's Gary Steel Works, Gary, Indiana. Axles are formed by a combination of rolling and forging. The axle bloom is rolled to wheel seat size and the forming is completed by hammer forging. After straightening, a lathe finishes the axle according to specifications.

Axles to help relieve the freight car shortage are loaded for shipment at U.S. Steel's Gary Steel Works, Gary, Indiana. Each of these 1020 pound axles will help American railroads roll their record peacetime consignments. The axles are forged from special steel and then machined. On the lower left giving a signal to the crane operator above is Bennis S. Blajsczak, assistant shipper, of 1736 Pennsylvania Street, Gary.

Over 3,000 rolls, ranging in size from 9 inches to 42 inches in diameter and weighing up to 25 tons each are shown in the roll storage yard at the U.S. Steel's Gary Steel Works, Gary, Indiana. There are over 10,000 rolls of various sizes and shapes in constant daily use at this plant. John Marietta and Mike Urschel, hookers, are the men in this picture. (Russell C. Aikins, photographer)

The loss of an arm doesn't mean the loss of a welding career to Frank Pishkur at U.S. Steel's Gary Steel Works, Gary, Indiana. Before entering the service, Frank was training as a welder. During the Battle of Germany as a staff sergeant in the famed 1st Infantry Division, Frank was hit in the right arm by an exploding artillery shell. In a field hospital it was found necessary to amputate the arm at the shoulder. Frank returned to Gary Works and with special training is now a skilled welder in the Welding Shop.

Technique of fighting a tar fire is demonstrated by plant protection personnel of U.S. Steel's Gary Steel Works, Gary, Indiana, with 1½ inch "paradise" nozzle.

Plant Protection personnel look on as Joe Lump, fire chief in U.S. Steel's Gary Steel Works, Gary, Indiana, demonstrates proper technique in carrying a "victim" down a ladder.

A group of workers at U.S. Steel's Gary Steel Works, Gary, Indiana, are shown the correct method of extinguishing an electric motor fire with a carbon dioxide (CO2) extinguisher.

Ore Bridge Operators in U.S. Steel's Gary Steel Works, Gary, Indiana, are shown how to operate a carbon tetrachloride (C2Cl4) extinguisher.

Inhalator squad at U.S. Steel's Gary Steel Works, Gary, Indiana, practices proper method of resuscitation using the Schaefer Prone Pressure method combined with an auxiliary inhalator.

Inhalator squad at U.S. Steel's Gary Steel Works, Gary, Indiana, practices proper method of resuscitation using the Schaefer Prone Pressure method combined with an auxiliary inhalator.

Fred Bowers, assistant fire chief at U.S. Steel's Gary Steel Works, Gary Indiana, demonstrates to open hearth workers the downward course of gasoline fumes.

A new employee receives safety instruction at U.S. Steel's Gary Steel Works, Gary, Indiana. Although grinder has a safety guard, goggles are an added precaution.

Safety instruction to the new employee at U.S. Steel's Gary Steel Works, Gary, Indiana, regarding the safe way to cut wire on bundles of steel.

BIRD'S EYE VIEW of a portion of the world's largest steel mill, the Gary, Indiana, Works of United States Steel. In the background on the right can be seen six of the plants twelve blast furnaces and on the left two of the open hearth shops. (Fritz Henle, photographer)